Smart worker assistance systems for more safety and efficiency

In an increasingly complex working world, assistance systems are a welcome help. They benefit machine operators and operators alike. By acquiring, processing and providing valuable information, the innovative systems make the use of production facilities, medical equipment or commercial vehicles safer, easier and more effective.

In production plants, malfunctions can be eliminated sustainably through the targeted use of worker assistance systems - and this with a significant reduction in scrap, operating time and personnel costs. In addition, the innovative systems increase production capacities, improve process reliability and also increase user-friendliness.

With a worker assistance system, you can make work processes more precise, reduce operating costs, significantly minimize wear on your machines, and thus ensure consistently high production quality at lower costs.

Advantages of worker assistance systems in mechanical engineering

Safe operation through direct provision of knowledge and feedback to operators

Reduced risk of overload or misuse

Increased productivity through optimized utilization of the machines

More consistent quality and efficiency with less training required

Learn more about our solutions for worker assistance systems. Arrange a non-binding appointment directly. Or send us an e-mail for more information.

Innovative worker assistance systems for a wide range of applications

Production facilities

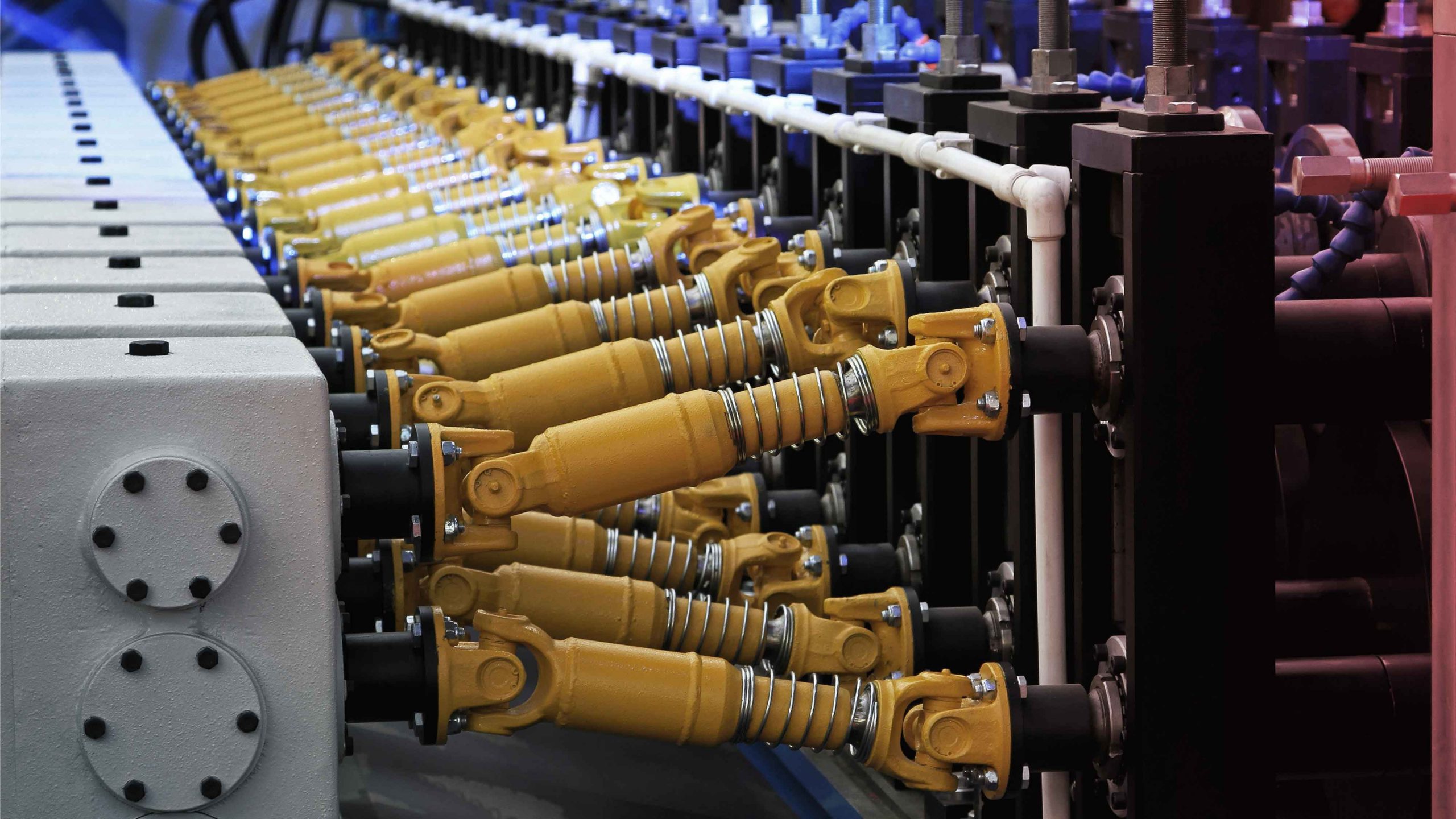

Assistance systems in production plants facilitate the set-up and setup of machines and ensure the quality of processes. Machine operators find the right parameters more quickly thanks to direct feedback. To this end, measured values are automatically recorded and the operator is warned in the event of a deviation. One example of the use of worker assistance systems in production is our customer Dreistern. The company monitors the quality-critical process step of straightening with the help of our coreIN sensors in combination with an individual app.

Commercial vehicles

Commercial vehicles are generally used in harsh environmental conditions where they are exposed to extreme loads. In addition, the forces and torques acting during their use lead to high stresses on the vehicles and their components. However, assistance systems in commercial vehicles - for example, for force detection when drilling with pile drivers and rotary drilling rigs, or load indicators in trucks - help to avoid overloads and increase safety during operation. In addition, worker assistance systems also guarantee the greatest possible precision when weighing materials or grading work.

Medical Technology

In medical technology, assistance systems are an asset in many areas. Their range of applications extends from therapy and therapeutic aids to rehabilitation. For example, operator assistance systems support surgeons by detecting interaction forces and surgical fields, thus ensuring safe and gentle interventions. Or they make it easier for patients with neurological impairments or after operations to regain lost abilities as a component of rehabilitation devices.

core sensing - smart solutions for innovative customized worker assistance systems

Our worker assistance systems offer you decisive competitive advantages and added value for your processes. From commissioning to operation: assistance systems from core sensing extend the service life of your machines and guarantee smooth operation. They identify potential sources of error, monitor machine conditions and provide you with immediate support for maintenance and servicing - in real time and directly from the machine.

Faster commissioning

(Re)finding the right settings and parameters is often done manually and requires time and expert knowledge. However, worker assistance systems make commissioning your machines and commercial vehicles much easier. By making process forces visible and showing operators which adjusting screws need to be changed for optimum machine settings.

Operate processes optimally

Machines should be operated as efficiently as possible without overloading them. Worker assistance systems enable you to make the best use of your machines by helping you make the right choices when operating commercial vehicles or production equipment.

Targeted maintenance

When identifying problems and process errors, worker assistance systems support you in identifying the correct error sources. The load history is recorded and evaluated by means of permanent logging. This means that employees are directly able to find and rectify errors independently, even in complex machines.

With core sensing simply to your individual worker assistance system

Our hardware and software solutions enable the rapid implementation of various functions for your worker assistance system. This gives you the opportunity to easily set up your individual system on an existing basis and thus secure your unique competitive advantage. Our solutions offer you the following technical features for this purpose:

Standardized algorithms and rules

- Customizable rules and algorithms for control

- Intelligent notification management

- Software toolbox for event detection, load cycle counter and FFT analysis

Visualization features

- Conceptual design and implementation of an intuitive user interface

- Individual dashboards and widgets for coreCLOUD

- Implementation of a user feedback system

Sensors

- Sensors for recording the process variables essential for the implementation of your assistance system

- Possibility to integrate third-party sensors

Connectivity

- Wireless measurement amplifiers with Bluetooth 5.0 connectivity

- Intelligent energy management

- Cloud platform for secure data collection and visualization

Our worker assistance systems in practice

Would you like to learn how to successfully implement assistance systems in your company?