Applications for electromobility

The topics of electromobility and traffic change are currently omnipresent in newspapers and news. In 2019, almost every 3rd bicycle sold in Germany was an e-bike, according to statistics from the Zweirad-Industrie-Verband (ZIV). There is a good reason for the resounding success of e-bikes: built-in torque sensors have enabled the motor control to be optimized so that an e-bike rides like a normal bicycle, with the difference that it always feels like there is a tailwind and a slight downhill gradient - even when going uphill.

Many other electrically assisted micro-vehicles are currently being developed or presented to the market. Whether electrically assisted baby carriages, electric scooters or electrically assisted logistics carts. The principle is always the same: A (push) force generated by the user is detected by a sensor and amplified via the electric motor. core sensing offers the corresponding sensor solutions to turn a conventional handle into an intuitive but unobtrusive operator interface.

Possible fields of application

- Intralogistics

- Golf Caddies / Golf Trolleys

- E-stroller

- E-Scooter

- Electric lawn mower

- E-bikes

- E-wheelchairs

Would you like to learn more about our sensor technology and the possible applications in electromobility? Simply request further information.

Sensor technology for e-mobility - application examples

Drive control by thrust force

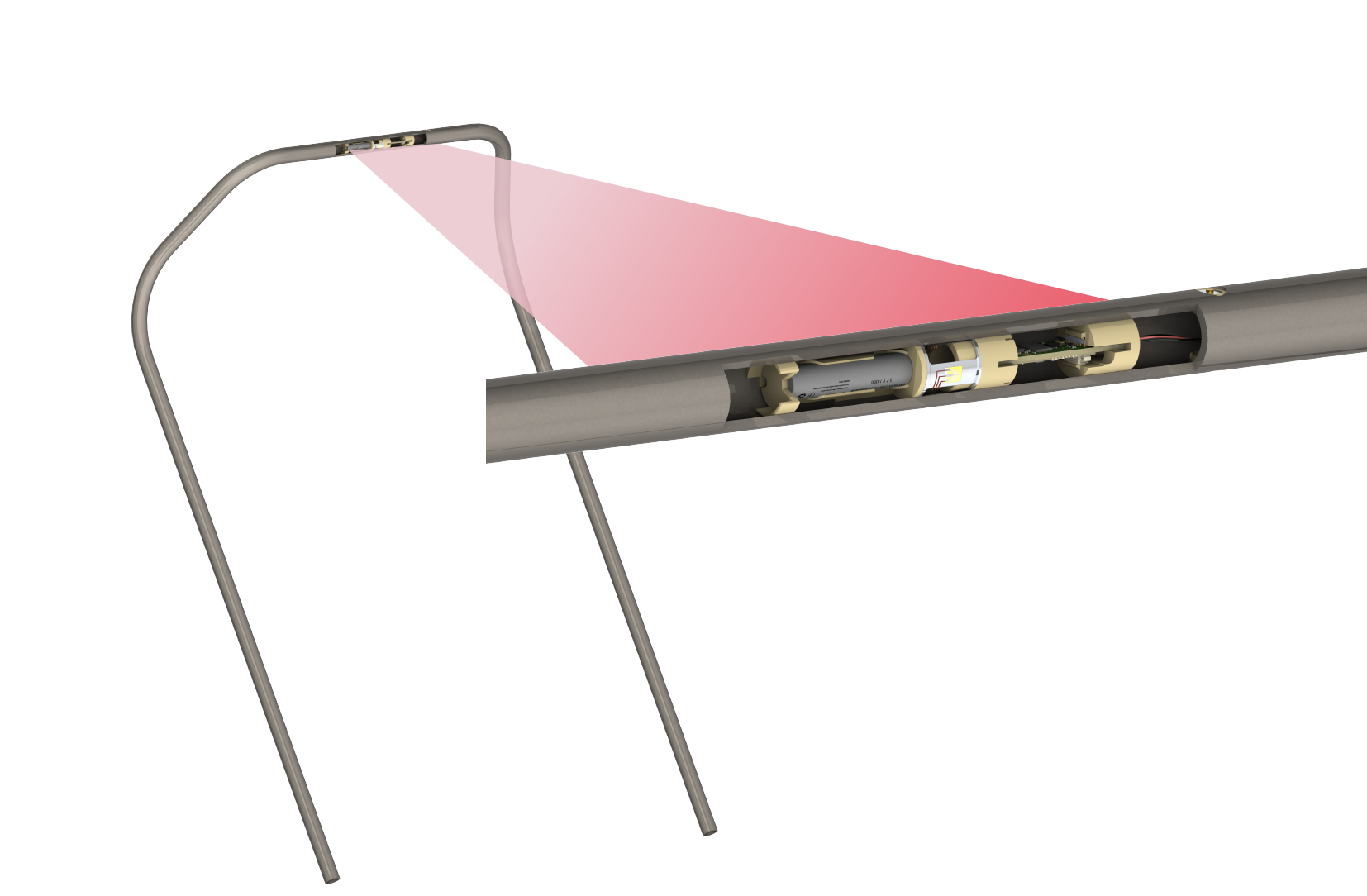

With the help of our sensor handles and a solution specially tailored to the application, we integrate lateral force or bending sensors into hand-guided, electrically assisted vehicles for transporting loads, people or performing heavy tasks.

An app can be used to set support levels, read battery runtime or other user interactions. With the help of our modular software modules, we would be happy to develop an individual user app for your application.

Drive control by torsion

With our integrated torque sensors, we transform a conventional handle into a throttle grip. To operate this, however, no actual movement, but only an introduction of force is necessary. The particular advantage, in addition to the clean look, is the additional safety, as both hands remain on the handlebars with full force and neither need to be turned nor the thumb released to drive.

This form of intention control is particularly well suited in cases where conventional rotary throttle grips or a thumb throttle have previously been used.

Intention control through torsion

By integrating a torque sensor into the handle, intentions can be detected and discrete commands triggered. For example, by twisting the right handle on the e-bike, the support level can be switched - 100% intuitively and safely . Through another pattern, which the user couples in via the torque, the menu navigation or further commands, such as flashing, can be realized.

Advantages of the IoT sensors from core sensing

Our sensors not only measure forces and torques, but also record a variety of other measured variables, such as speed, accelerations and temperature. Not only that: the robust, wireless sensors are protected inside the components and thus provide safe, reliable sensor values. Simply benefit from the following advantages:

Optimized for rotating and moving parts

Our performance begins where conventional manufacturers and transducers reach their limits. Our sensors can be integrated very easily into existing designs - whether as standard components or individual parts.

Optimized for harsh and demanding environment

Due to the sensor integration inside the component, our sensors are excellently protected against external influences.

Optimized for wireless use

Our sensors not only measure forces and torques, but also record a variety of other measured variables, such as speed, accelerations and temperature.

Sensor technology for electromobility in practice

Drive shaft with integrated sensors

Determining the loads in the development of e-cars is a major challenge. The integrated sensor coreIN creates new insights in this regard.

Learn more about our Predictive Maintenance solution. Arrange your non-binding appointment directly.