Our Use Cases - Smart Sensors, Smart Algorithms, Tangible Added Value

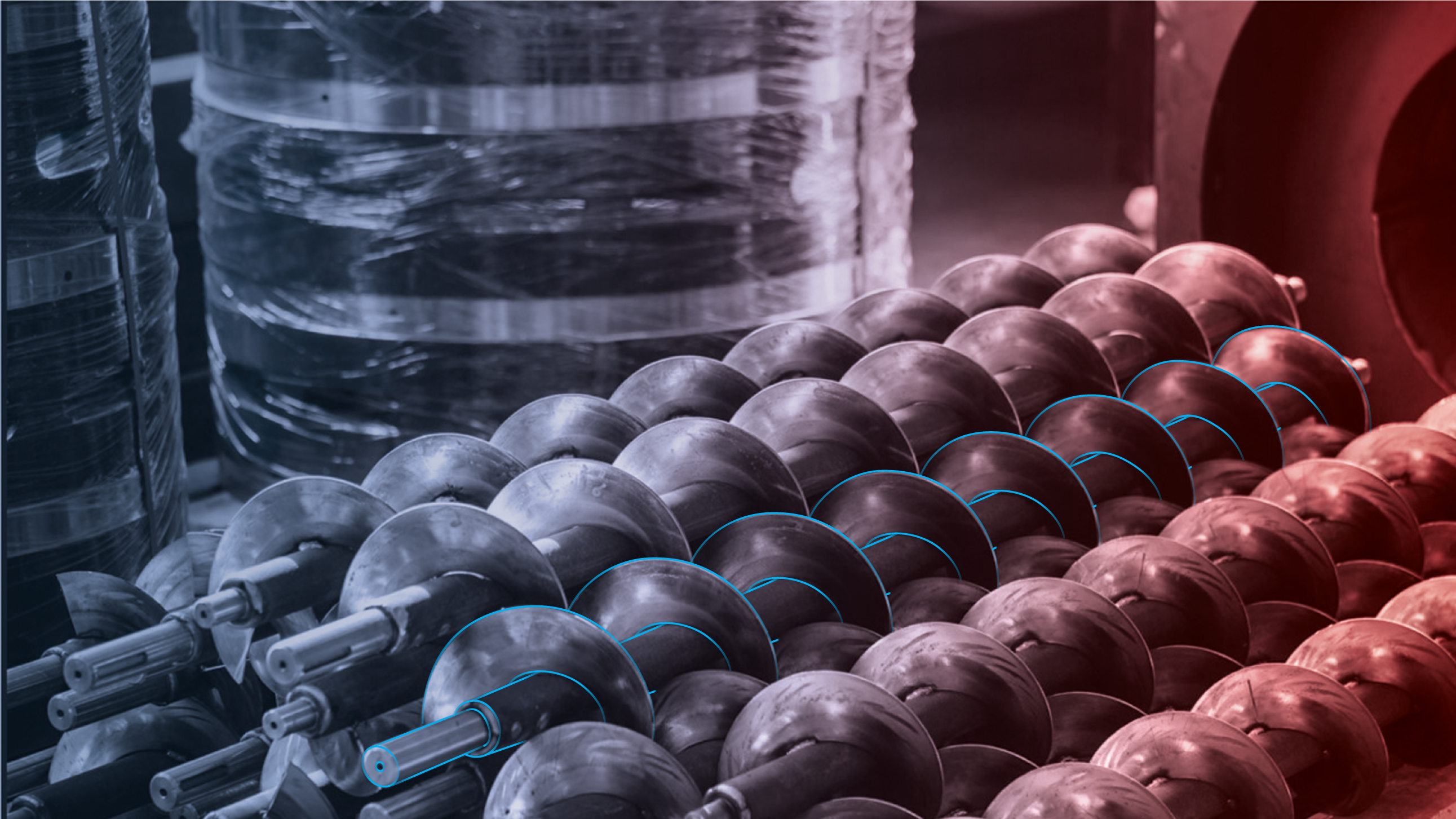

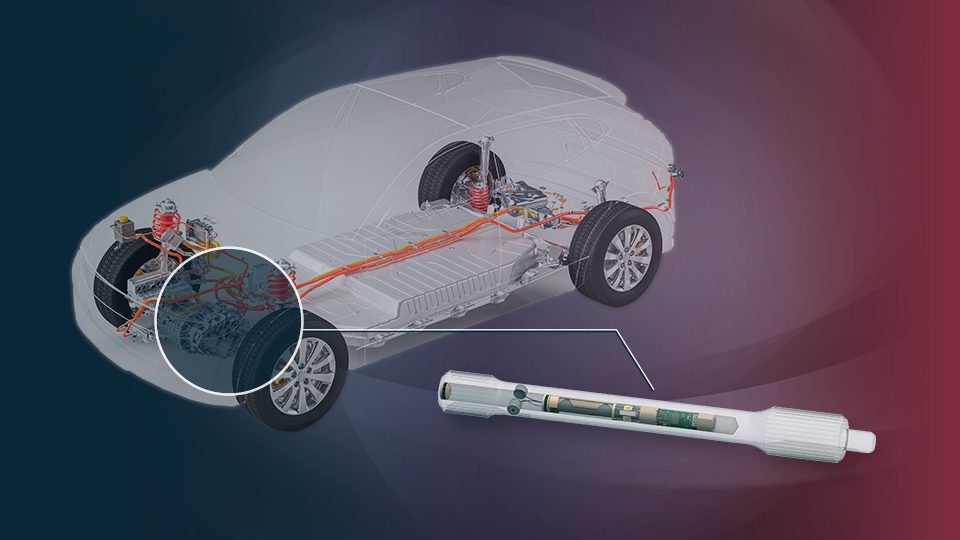

Sensors, measurement amplifiers and software products from core sensing are used in a wide variety of projects and industries, such as Machines & Plants, E-mobility, Sport & Rehab as well as Commercial vehicles, for use. Despite the modularity, our solutions are always individual and surprise with their diverse areas of application.

Learn more about the different added values realized with the help of our hardware and software solutions and how core sensing supports its customers and partners in digital product development and introduction.

Alle

Assistance Systems

Automated Documentation

Condition monitoring

Measurement projects

Partnerships

Predictive Maintenance

Keine Ergebnisse gefunden

- Condition monitoring

to the customer project

- Measurement projects, Partnerships

to the customer project

- Assistance Systems, Partnerships, Predictive Maintenance

to the customer project

- Assistance Systems, Condition monitoring

to the customer project

- Predictive Maintenance

to the customer project

- Assistance Systems, Predictive Maintenance

to the customer project

- Automated Documentation, Condition monitoring

to the customer project

- Measurement projects

to the customer project

- Partnerships

to the customer project

- Measurement projects

to the customer project

- Measurement projects

to the customer project

- Predictive Maintenance

to the customer project

- Automated Documentation

to the customer project

Show more

Would you like to be informed about the latest use cases?

Then simply enter your e-mail address for the newsletter.