On May 14 and 15, 2024, the Dresden Colloquium on Machine Elements (DMK 2024) opens its doors to present the latest achievements in the fields of machine elements, drive technology, sensor technology and artificial intelligence. Particular attention will be paid to the combination of traditional machine elements with state-of-the-art sensor technology to create so-called "sensor-integrating machine elements".

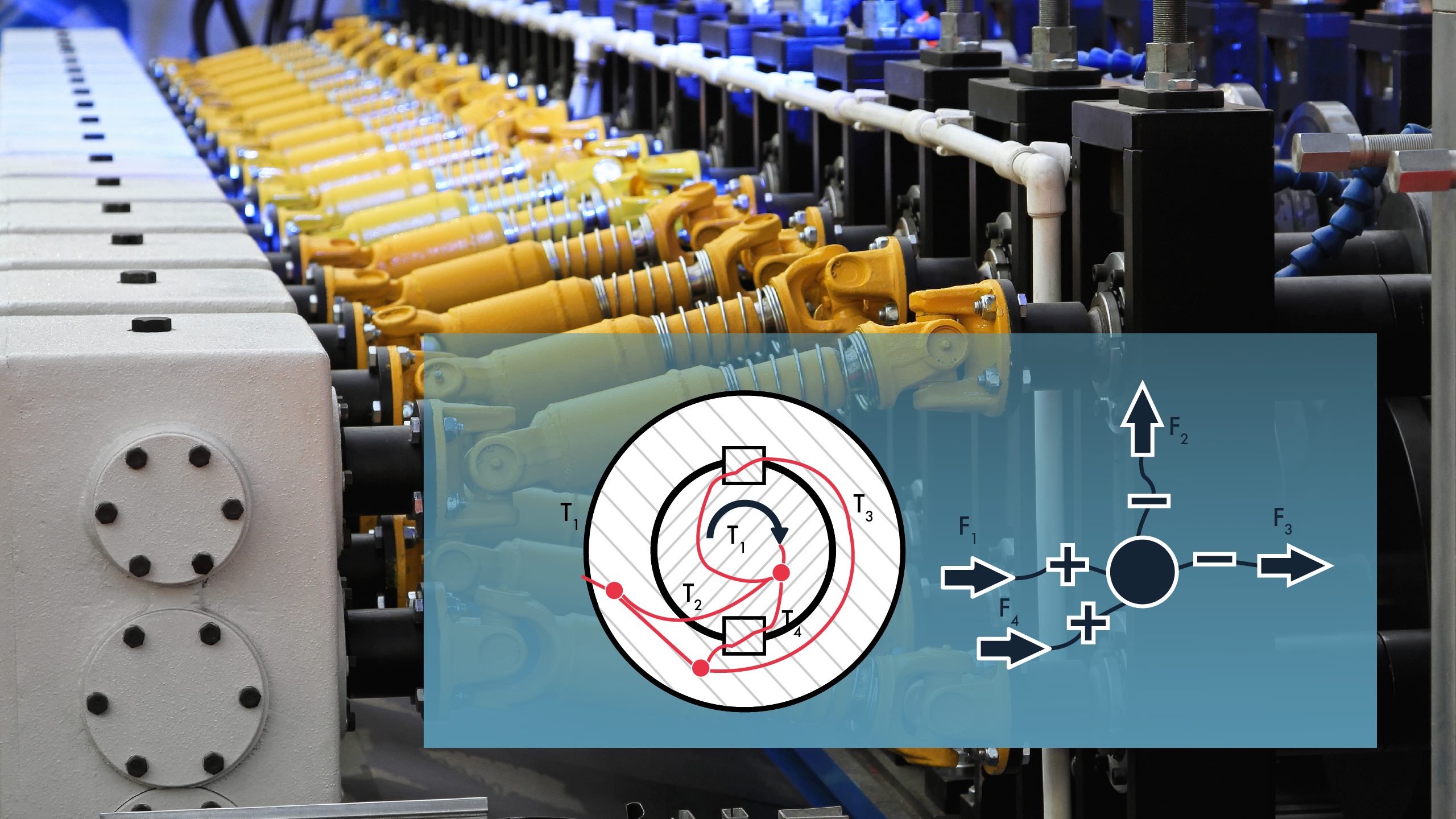

Core Sensing will also be there to show how a roll forming system is analyzed using a methodical approach in order to select the right machine elements and further develop them into sensor-integrated machine elements.

DMK 2024: Advanced approaches and potential of the fusion of machine elements and sensor technology"

DMK 2024 offers an outstanding opportunity to find out about the most advanced approaches that are having a significant impact on the industry. From the integration of intelligent sensors to increase efficiency to the diverse possibilities that digitalization offers for the optimization of production processes and the development of intelligent machines, exciting perspectives are opening up. With 48 presentations from the fields of machine elements and drive technology, the conference program promises a wide range of offerings from industry and science. Both tried-and-tested solutions and the latest developments will be presented and discussed across industries and disciplines in order to provide valuable impetus for all participants.

The fusion of machine elements and sensor technology holds enormous potential for the future of industry. Through the intelligent integration of sensor technology, machines can not only work more efficiently, but also act more predictively and autonomously. This leads to an increase in productivity and quality in various sectors and enables innovative solutions for future challenges.

Innovative concept for optimizing machine elements: Load path and node model in the focus of the presentation by core sensing, Dreistern and Elbe & Elso at the Dresden Machine Elements Colloquium

Our colleague Dr. Sven Vogel, together with our partner Patryk Pika from Elso Elbe GmbH & Co. KGand Prof. Dr. Tilman Traub, formerly of Dreistern GmbH & Co. KG, will give a lecture on "Selection and development of sensor-integrated machine elements using the load path and node model". The application of this model for the further development of machine elements will be explained in more detail and the associated advantages will be highlighted. In particular, the load path and node model for evaluating replacement variables in the product development of mechatronic systems will be presented using the example of a roll forming system. The presentation promises a deep insight into innovative approaches in the implementation of digitalization and optimization of systems and their practical application. The speakers will also present the joint innovative development of the sensory cardan shaft.

Contribution: Development of sensor-integrating machine elements using a load path and node model

Sensor-integrated machine elements enable more precise process monitoring, faster commissioning and reduce dependence on operator knowledge.