IoT sensor integration - Right at the heart of demanding measurement tasks in future.

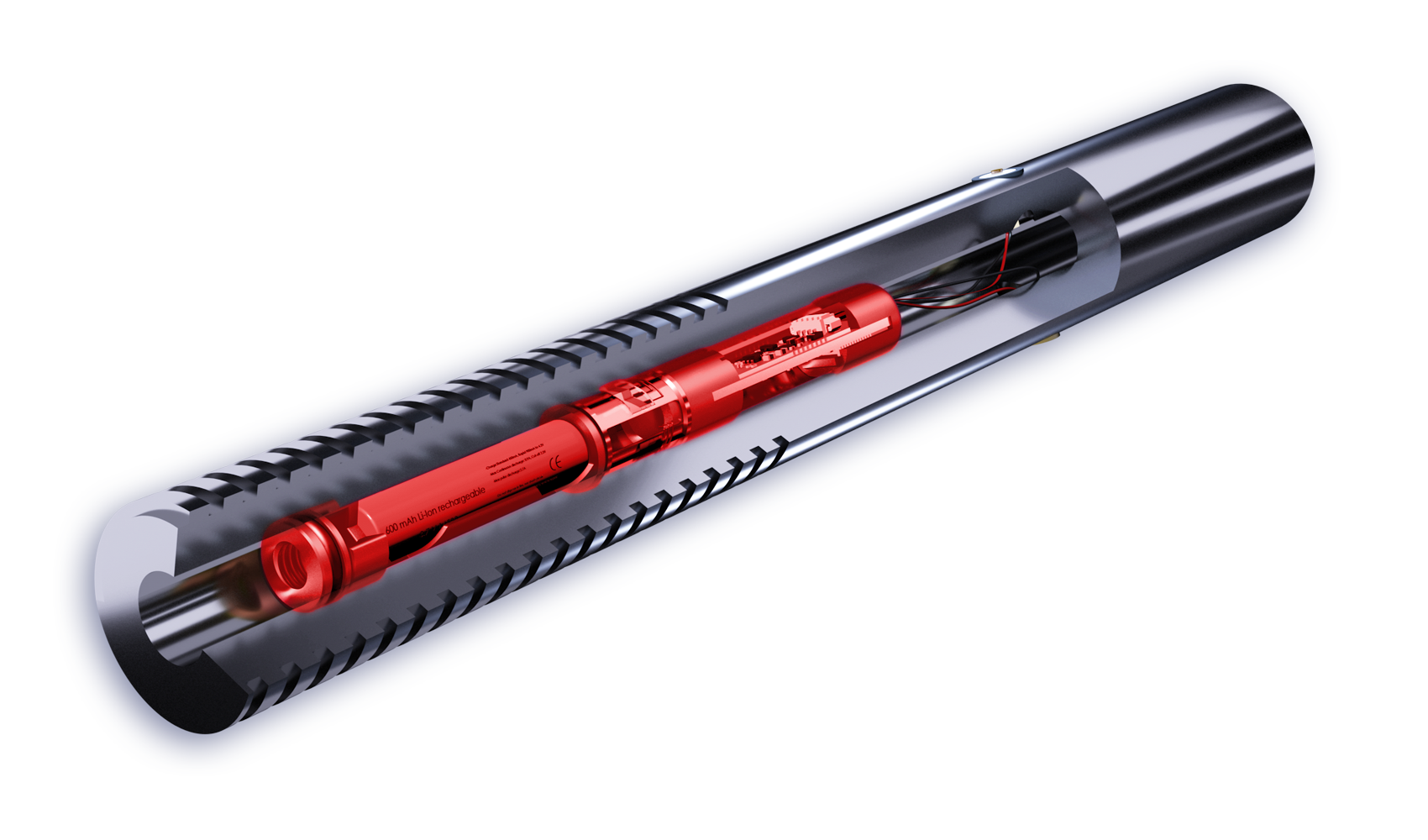

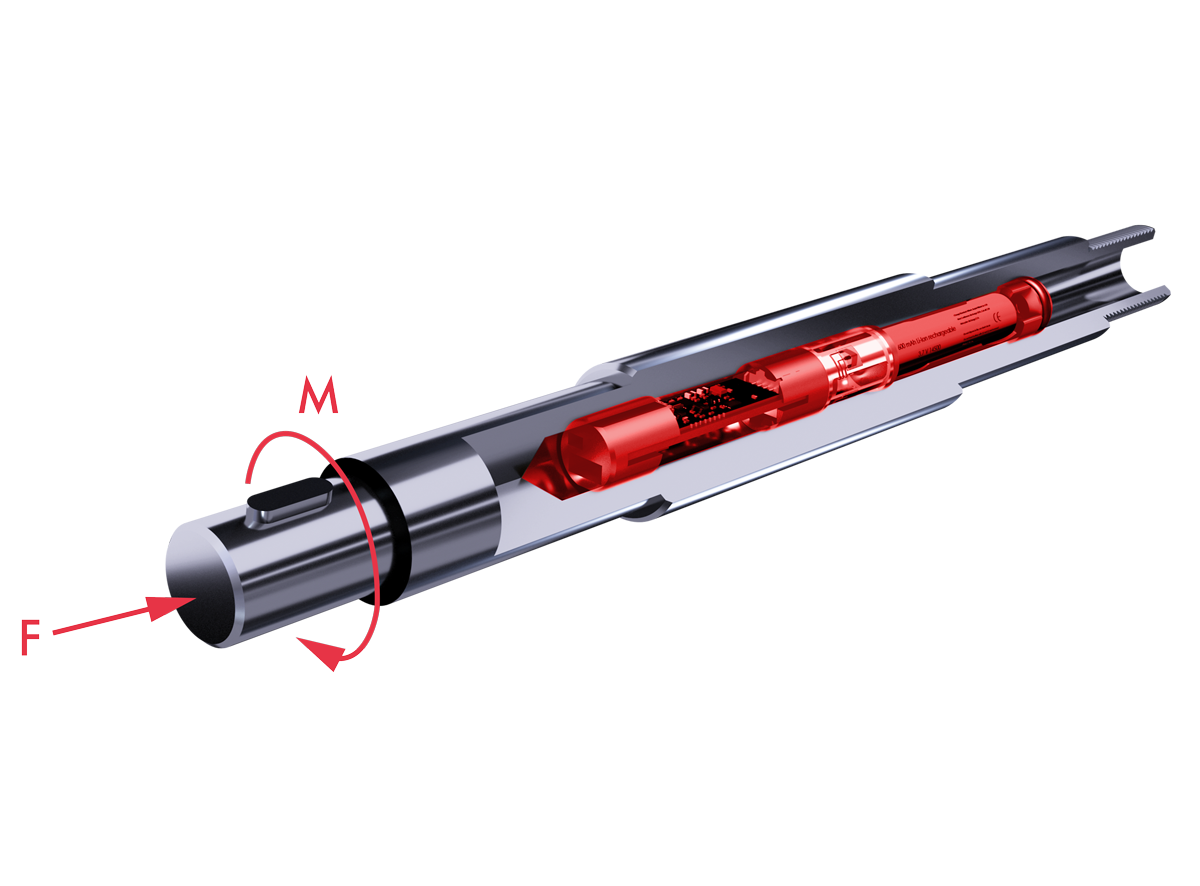

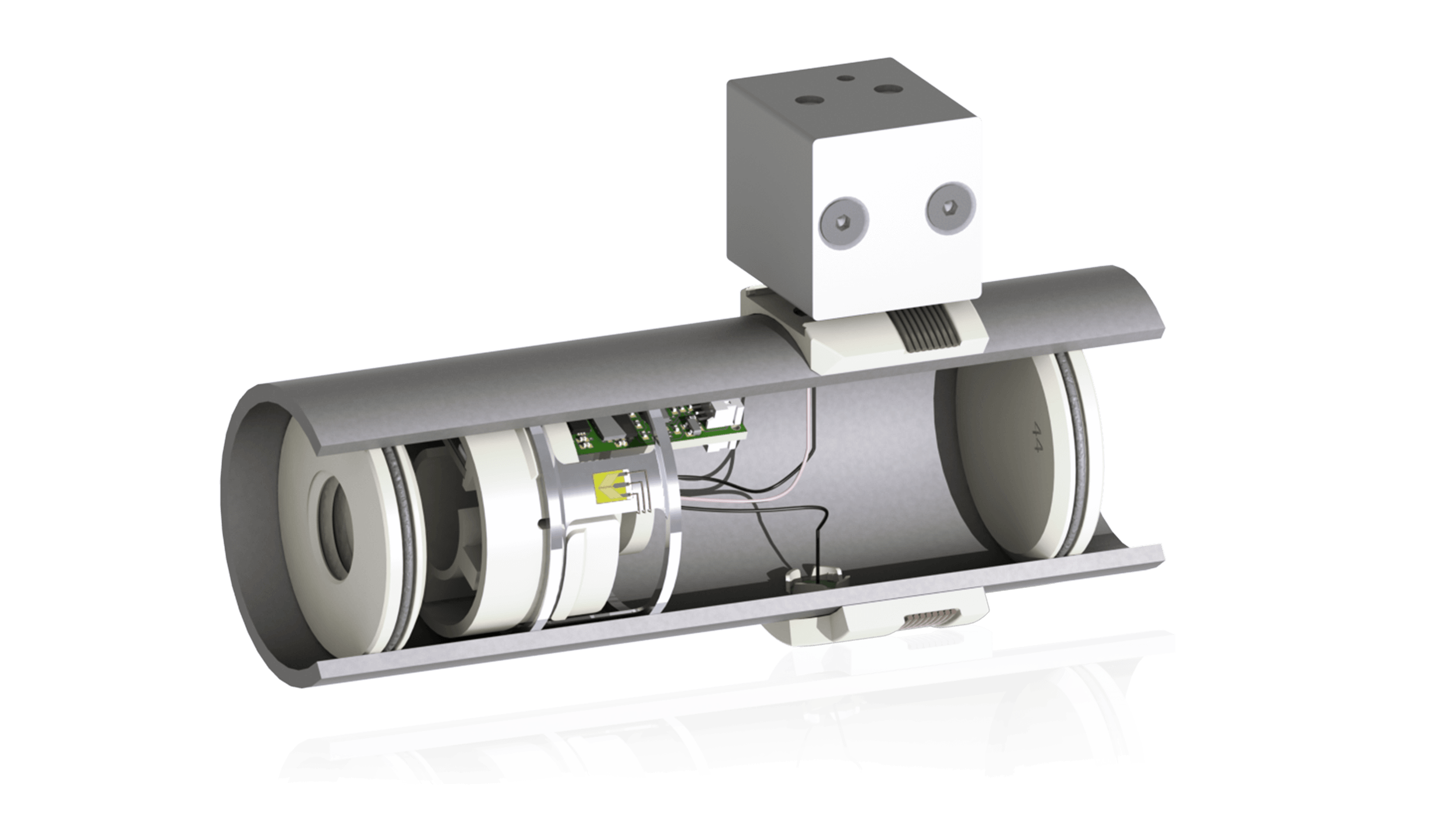

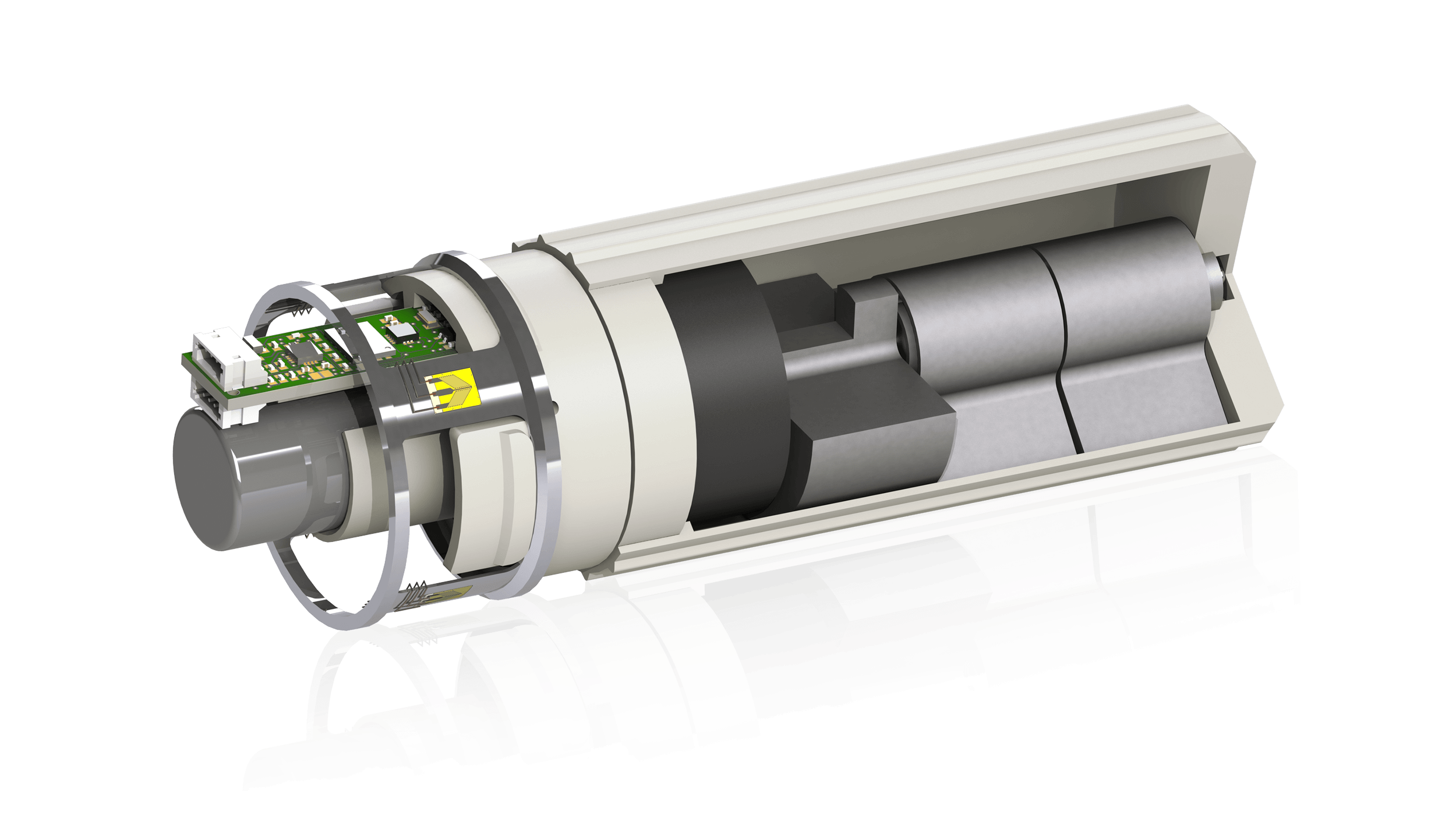

Now you can record loads safely and reliably where the measurement data provides the greatest added value: directly in the component. By transforming mechanical machine parts into intuitive and individual smart IoT sensors. Quite simply. With our universal sensor integration coreIN.

The strain gauge-based deformation body measures forces, bending moments and torques and is individually configured to your application. The robust and reliable integrated force sensor / torque sensor coreIN is available in the desired quantity to suit your requirements - from single units to series production. In addition, the coreIN sensor integration has a modular design for almost limitless areas of application and is available in various sizes and energy options.

coreIN in short portrait

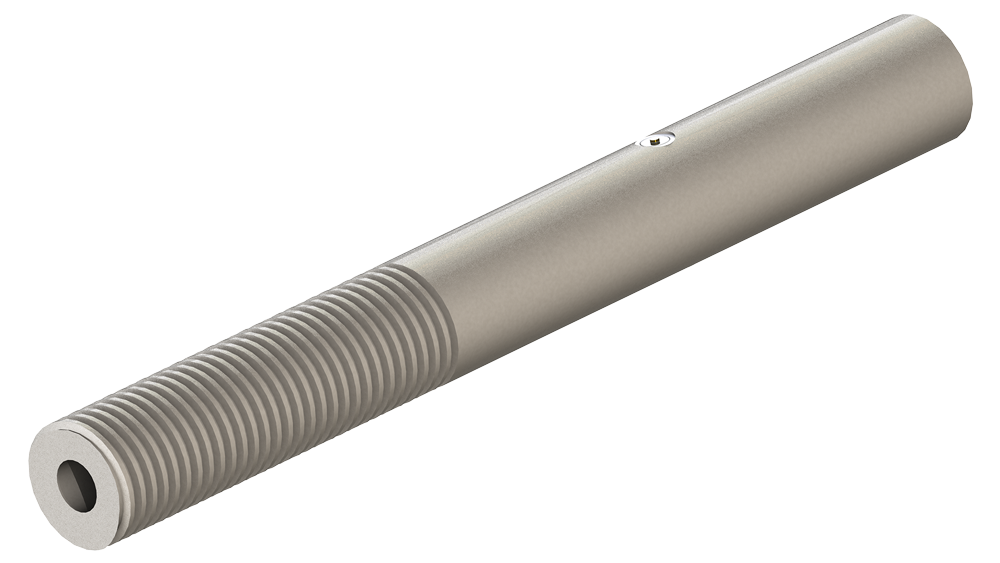

- For tubes or drilled components with an inner diameter of 14 mm or more

- Integrated IoT sensor & measurement electronics protected inside the component

- Measurement of torque, force, bending or shear force

- Additional speed, acceleration and temperature sensor

- Various energy options (battery, induction, energy harvester or wired) available

- Further processing of the components possible

More than one sensor:

Four advantages in one component.

Learn more by clicking on the info points

More than one sensor:

Four advantages in one component.

Learn more by clicking on the info points

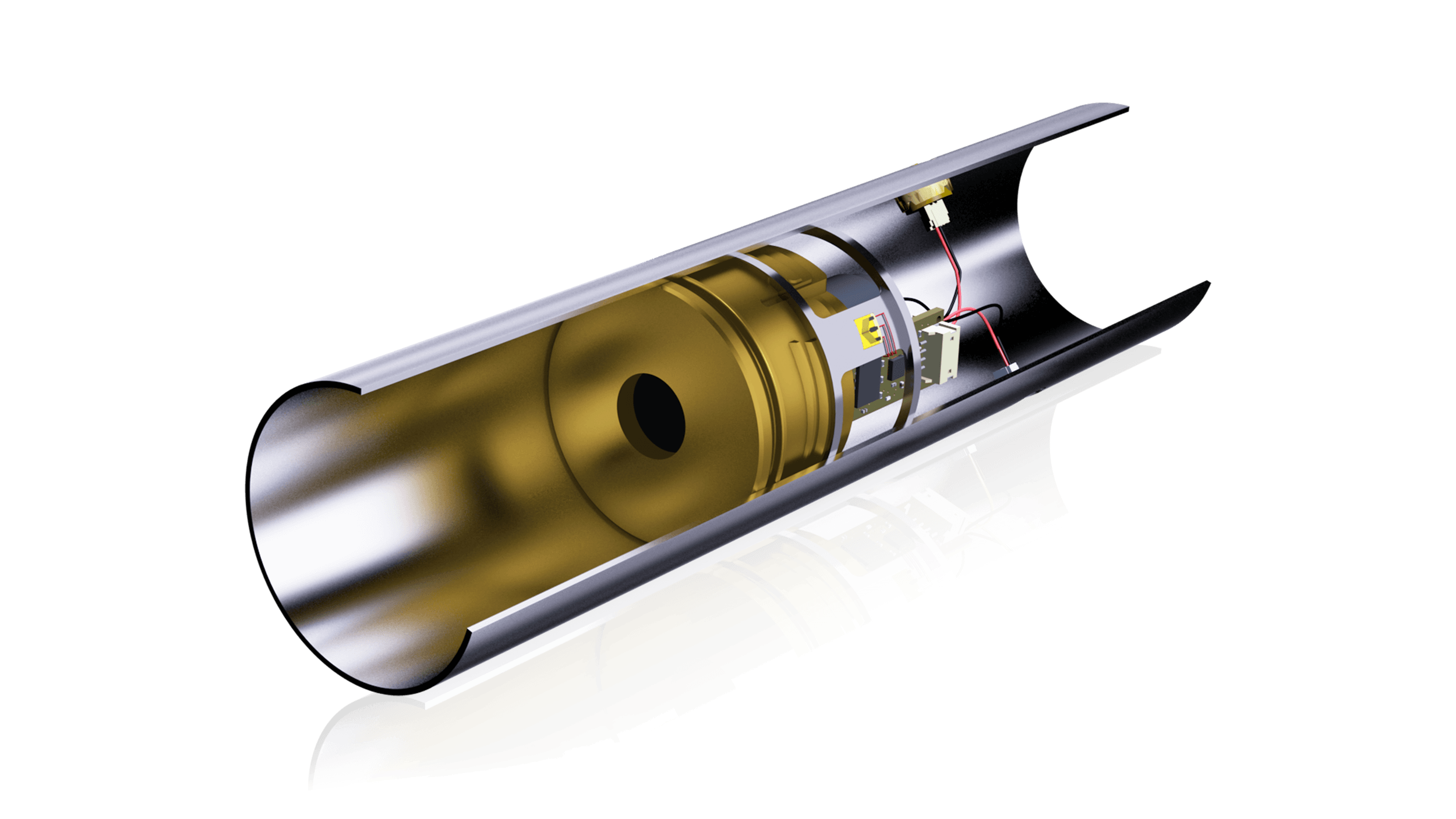

Your component - your smart force sensor

We integrate our measuring chain into your component and transform it into an intelligent and wireless force sensor according to your needs. It does not matter whether a tube structure or drilled solid material is present.

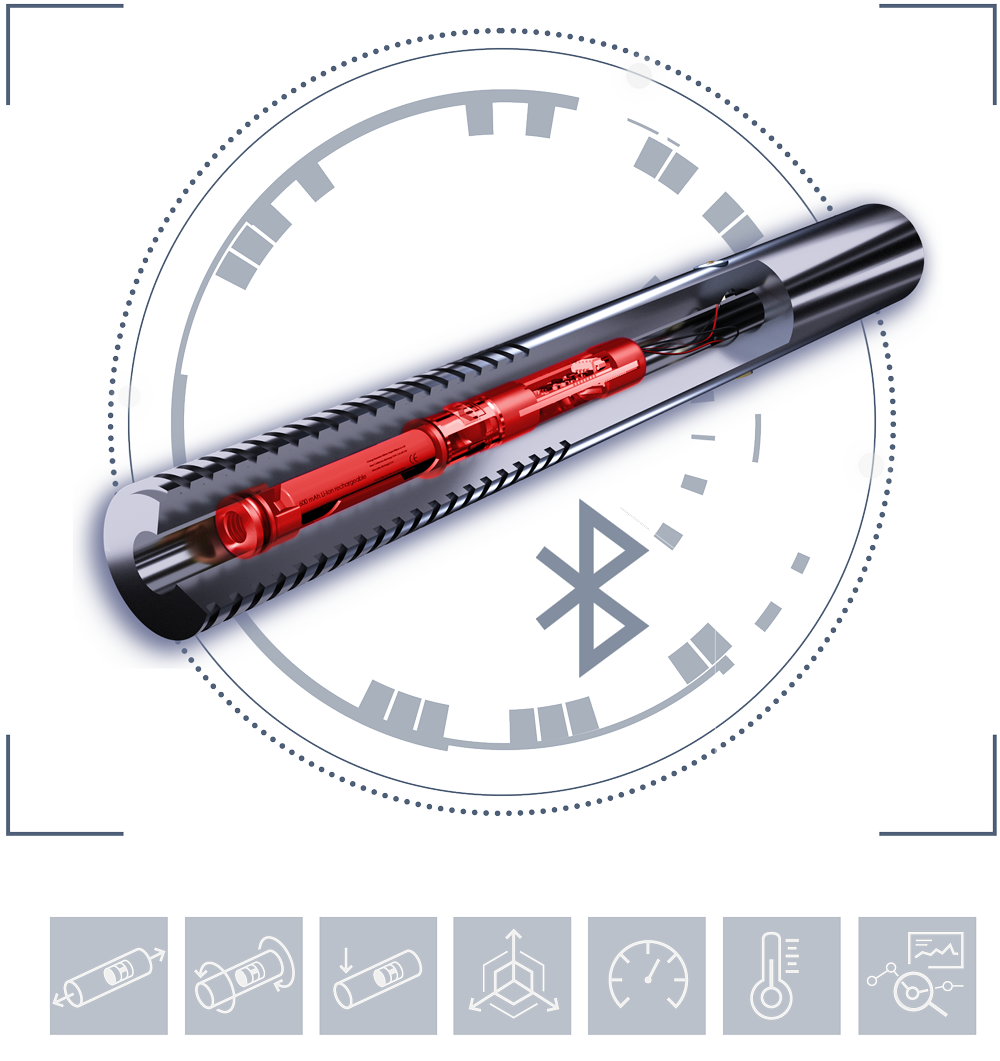

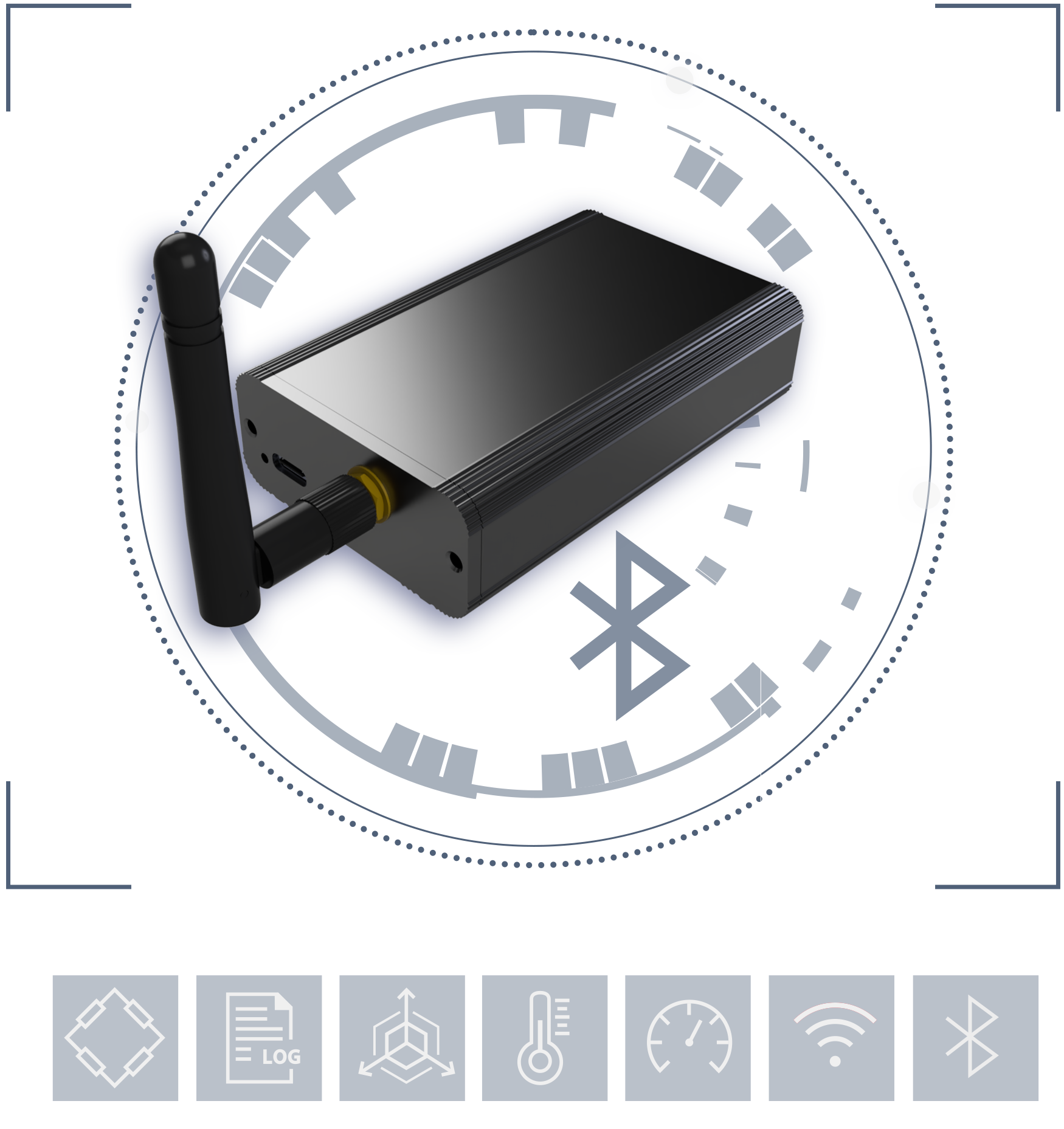

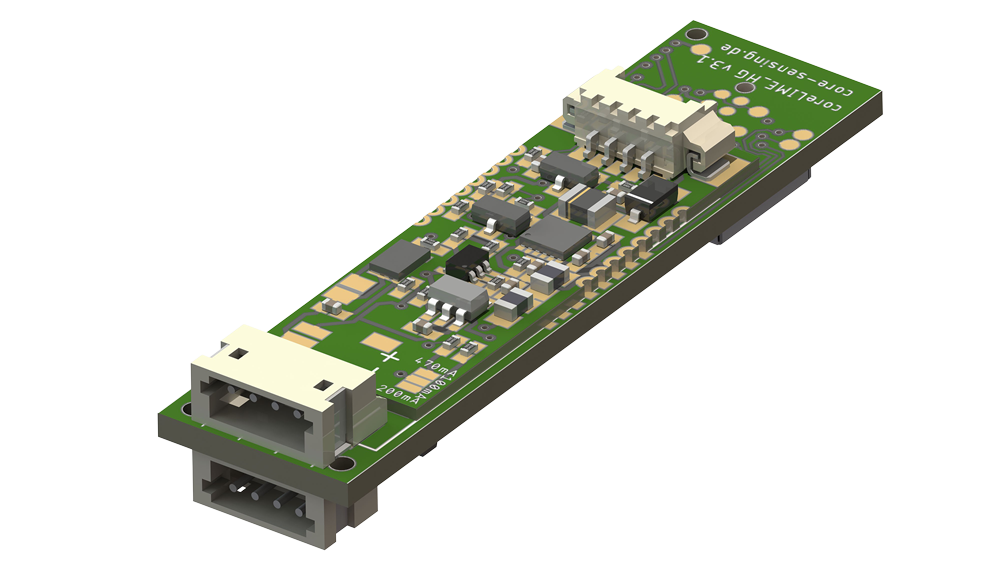

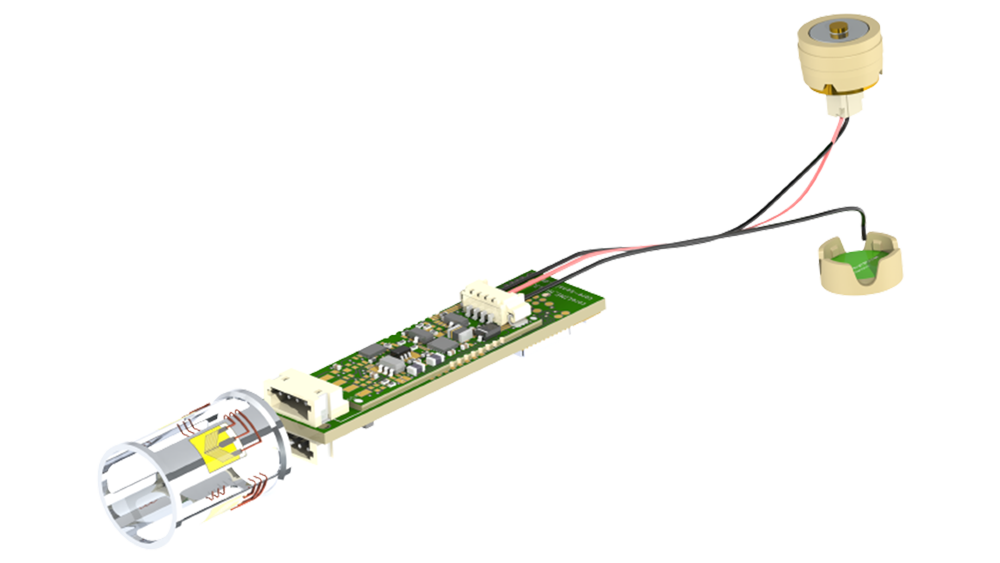

Measuring amplifier

Powerful and energy-saving measurement electronics. Two channels for strain gauge-based sensors with an additional inertial measurement unit enable a wide range of measured variables (such as speed, acceleration, temperature) to be recorded and processed synchronously.

Deformation body

We use the proven strain gauge technology. The connection between the deformation body and the component allows forces, bending and torques to be measured reliably and accurately.

Energy supply for every application

Whether temporary, mobile or permanent applications - we have the right power supply for your sensor application. Li-Ion batteries for mobile accessible measurements. Inductive power supply for permanently installed, non-accessible systems.

coreIN sensor integration - one solution, many results

At the heart of our force sensor / torque sensor coreIN is the powerful coreLIME measuring electronics.

It can be used to record and evaluate various measured variables:

Axial force

Standard measuring range

50 N - 125 000 N

Torque

Standard measuring range

25 Nm - 6 000 Nm

Shear force / bending

Transverse forces up to 100 kN

Acceleration

3-axis accelerometer up to 30 g

Speed

Standard measuring range

up to 2 500 RPM

Temperature

Integrated temperature monitoring

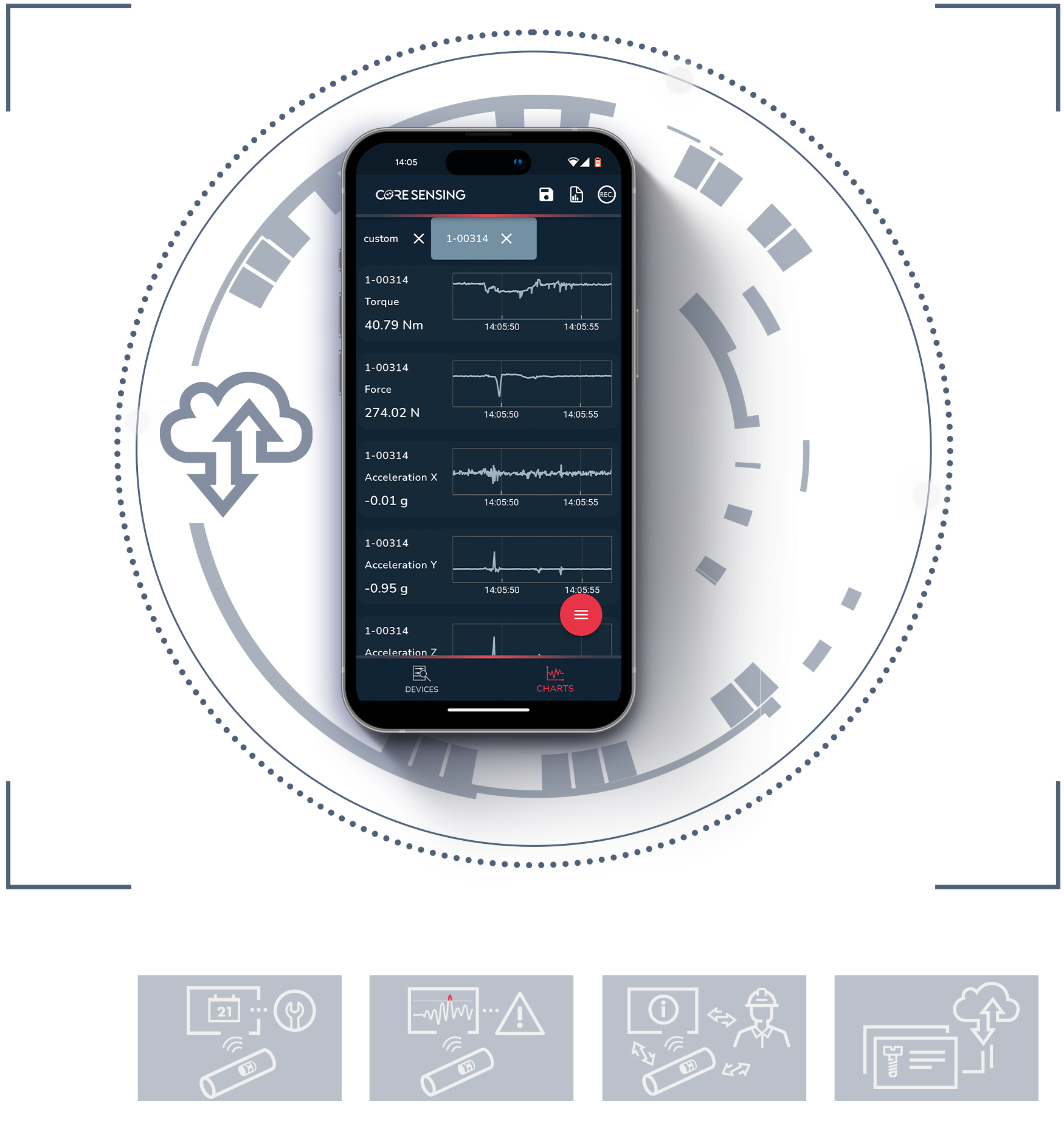

Monitoring

Saving signal curves

Interpretation

Real-time analysis of sensor data

Are you interested in the possibilities of our smart measurement technology?

We will be happy to advise you!

Fascinating: The smart measurement technology universe of core sensing

Learn more about our sensor solutions now

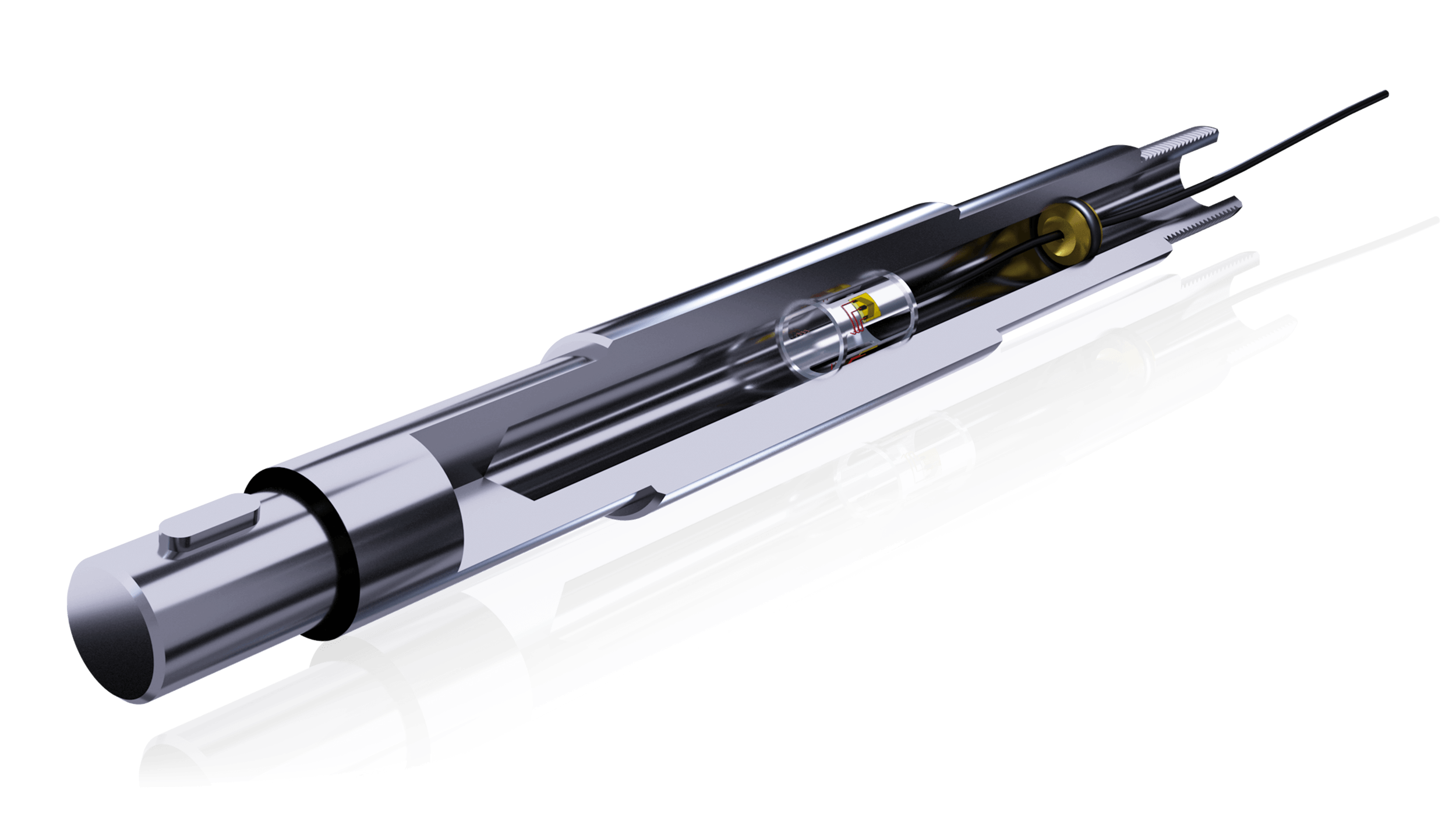

Measuring force and torque without limits - coreIN sensor integration adapts to your tasks

From large axles and shafts to small bent tubes: Set new standards for sensor components and parts. It's easy with coreIN sensor integration. Our smart force sensor / torque sensor fits into any component. You can even carry out tube processing steps such as bending or welding without any problems once it has been integrated. There are no limits to the variety of shapes.

Full of energy for reliable measured values - the perfect energy supply for every application

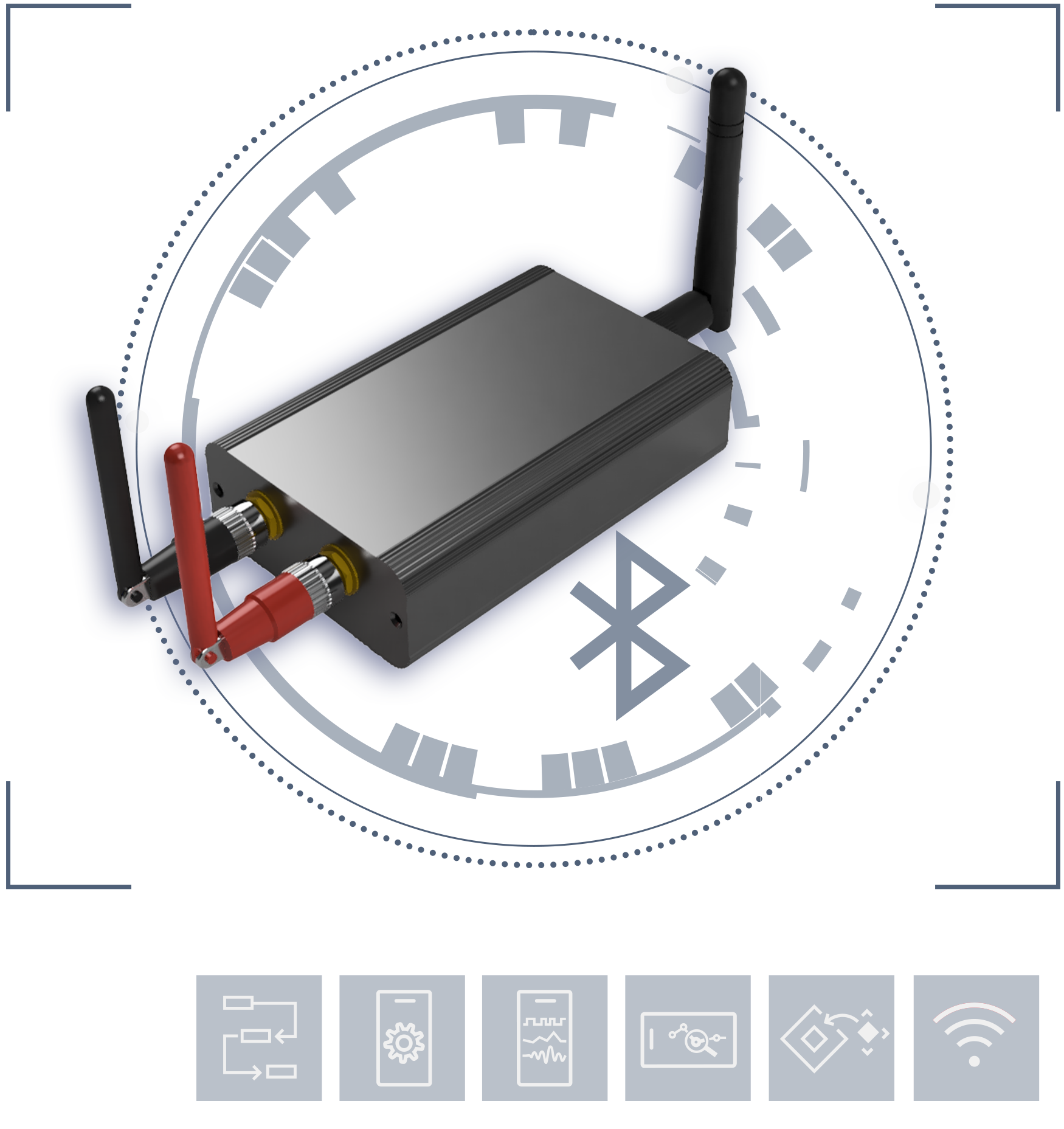

Whether in mobile or stationary use: with our modular force and torque sensor system, you always benefit from the full potential of coreIN. Simply combine the integrated IoT sensor with one of our miniaturized IoT sensor nodes to perfectly match the respective application scenario coreLIME or coreMOBILE and the appropriate energy supply concept from core sensing:

coreIN battery

Ideal for temporary measurements and mobile applications - thanks to efficient Li-Ion battery with integrated battery management system and energy saving mode.

- Replaceable, rechargeable battery

- Magnetic plug with USB charging option for powerbanks and USB power supplies

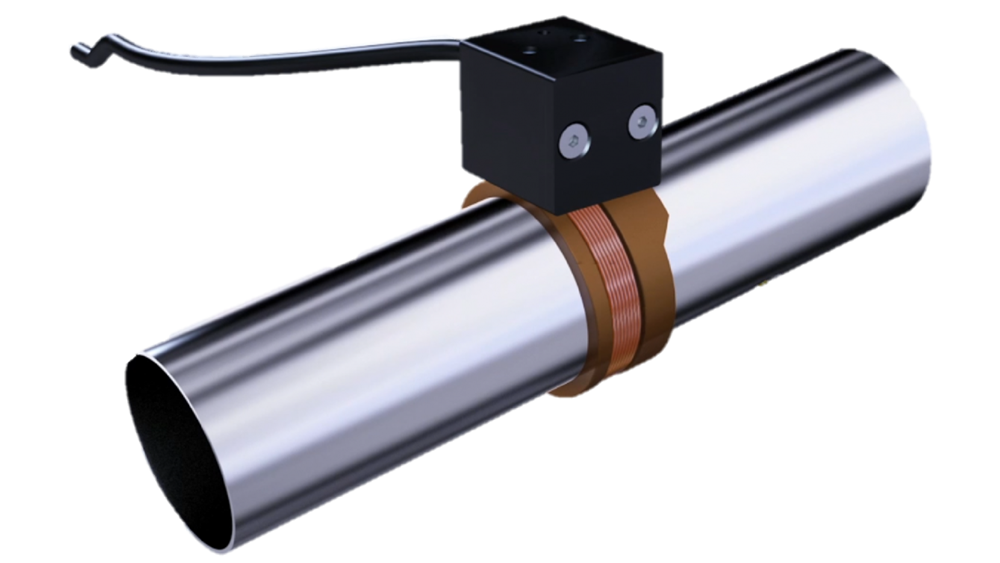

coreIN field

Ideal for permanent measurements - thanks to pickup head for an energy transfer via induction and integrated coreFIELD measurement amplifier.

- Permanent energy supply

- Integrated distance monitoring

coreIN harvest

Ideal for measurements on hard-to-reach components - thanks to self-sufficient energy generation by rotary energy harvester and integrated measuring amplifier.

- Energy-autonomous sensor for the drive train

- Additional battery for buffering

- Power generation by generator + fixed unbalance dimensions in earth gravity field

coreIN cable

Ideal for permanent measurements of non-rotating parts - thanks to cable-connected sensor for direct use of the full bridge with external measuring amplifiers

- 4-wire strain gauge full bridge

- Safe cable routing to the outside

- Connection of coreLIME or other measuring amplifiers

Configure your individual IoT sensor

With our configurator, you can create a customized IoT sensor even for small quantities, allowing you to cost-effectively gain initial experience of the monitoring options for your components.