Easier than ever: measure torques and power between tractor and implement

For some time now, modern agriculture has been relying on smart farming for greater efficiency. The key is accurate sensor readings that enable intelligent control of machinery and more economical processes. Powerful hardware and software makes these measurements possible - quickly, easily and precisely. In the context of smart farming, it is already possible to better coordinate a team of tractor and implement, for example.

Integrated torque sensors open up new possibilities

Torque sensors in the interface between tractor and implement play an important role in the increasing automation of agricultural machinery. Here, smart sensor technology enables control of the tractor that is optimally adapted to the soil conditions or the mown material and the use of machines at the optimum load point while avoiding overloads. In this way, the smart integrated torque sensors make a valuable contribution to greater efficiency and safety in agricultural processes in the context of smart agriculture.

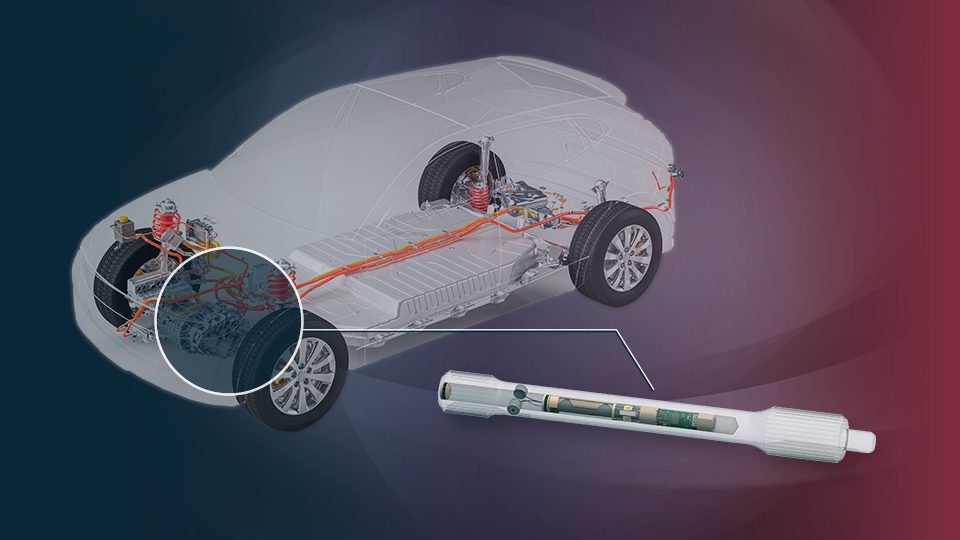

Smart PTO with integrated sensor from core sensing

Our intelligent PTO has a sensor integrated directly into the drive component. It thus allows full-fledged torque and power measurement during operation, including direct wireless transmission of the measurement data to a suitable interface.

This makes it possible, for example, to connect the cardan shaft to the vehicle control system or a diagnostic system for remote maintenance. Algorithms evaluate data here and detect, among other things, a possible overload or wear-related failures at an early stage. As a result, the reliability of the machine is increased, which can be further enhanced by load-oriented maintenance of the drive components.

Key facts intelligent cardan shaft

- Integrated power and torque measurement

- Accuracy: 0.5 - 1%

- Additional measured values: speed, temperature, acceleration (slope), location

- Energy self-sufficient thanks to energy-saving battery solution

- Safely protected by sensor integration in the inner profile shaft

- Torque / power range: up to 6,000 Nm / 350 kW

- For all typical speed ranges (540 or 1000 RPM)

- Data transmission via Bluetooth or mobile network (LTE-M)

- No external measuring amplifier necessary (Plug & Play)

Would you like to learn more about the smart PTO and its possible applications? Then request the free white paper on our smart PTO now.

Application examples of the integrated PTO shaft

Baler

- Regulation of bale discharge via torque measurement

- Up to 15% higher output due to higher travel speed

- Fully automated baling

- Improve productivity and quality

- Avoidance of engaging overload clutch and reduction of downtimes by replacing the shear bolts

Loading wagon

- Measurement of the compression of the load

- Recording the optimal utilization of the load

- Overload protection and protection of the components

- Additional monitoring of the cutterbar

Spreader

- More uniform spreading pattern or manure distribution with torque as controlled variable

- Automatic documentation of the application rate and location

- Time saving, since no uniform loading is necessary