Details you should know about coreIN

The force-fit pressing process of the coreIN deformation body applied with strain gauges is unique on the market. The pressing, i.e., the connection between the mechanical component and coreIN, is carried out at core sensing. As the number of OEM products increases, the process can be set up at the customer's site.

The strain gauges are applied to the compact geometry of the coreIN deformation bodies. This ensures that the appropriate tools and fixtures are available for high-quality application. All coreIN sensors are equipped with strain gauges using hot application.

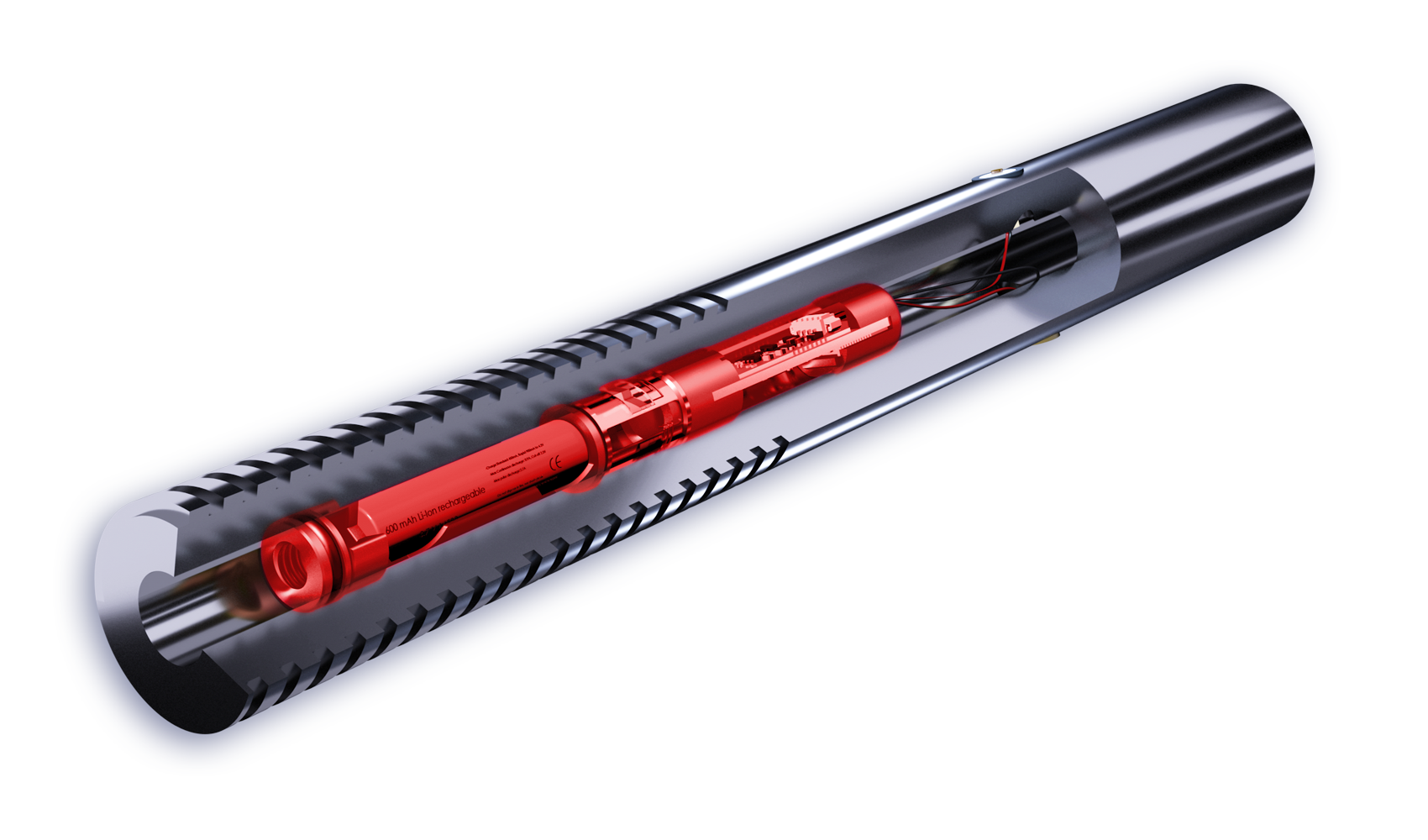

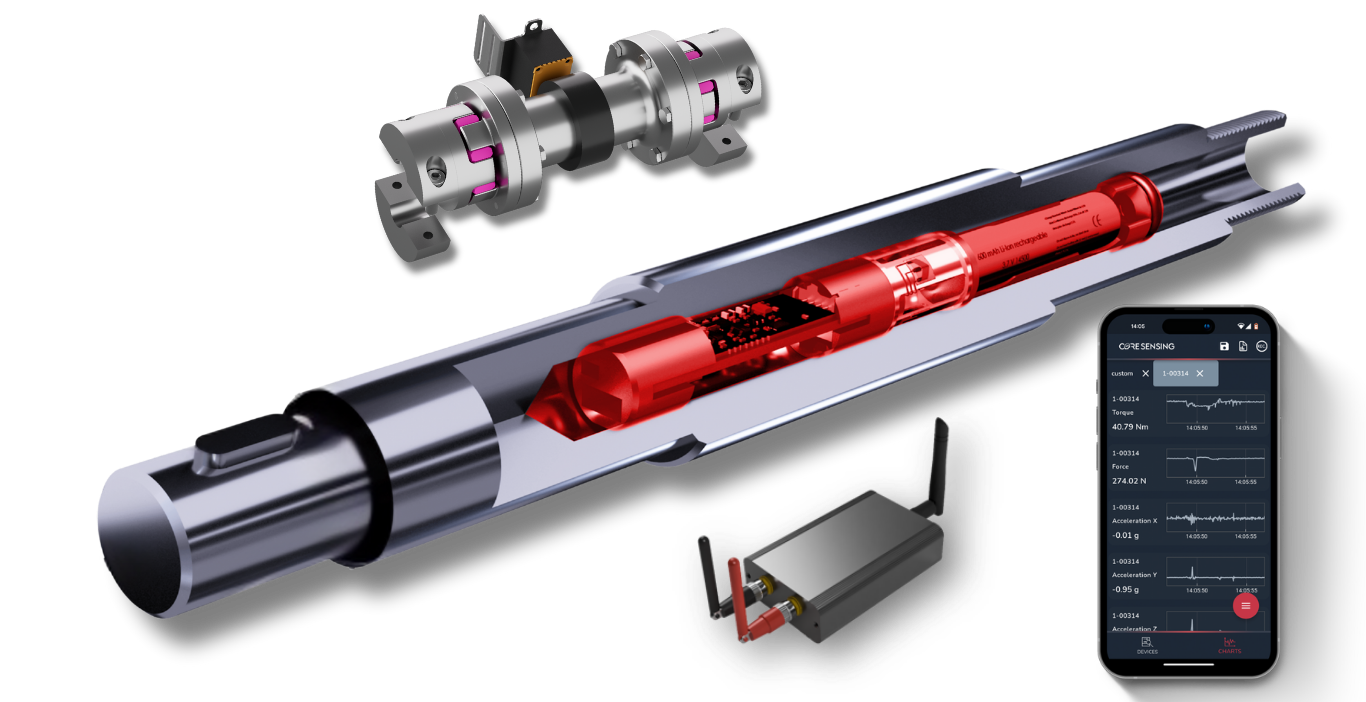

The required installation space for the individual components varies depending on the available internal diameter. The exact installation space analysis should be discussed during an orientation call. Here are a few key figures to give you an initial impression:

- Inner diameter 14 mm…100 mm

- Length coreIN approx. 30mm

- Length of standard measuring electronics approx. 50 mm

Data is usually transmitted via Bluetooth Low Energy. If the sensor is not a rotating or moving component, a wired solution may also

The standard power supply we have chosen is a rechargeable Li-ion battery with as high a capacity as the installation space allows. At higher temperatures or for continuous measurement tasks, a battery or inductive power supply can also be selected.

There is a conflict of objectives between maximizing the available data and energy efficiency. For this reason, the sensor can be configured individually. Additional sensors for speed, acceleration, and temperature are available as standard. The transmission rate is a maximum of 1,000 sPs.

There are many ways to obtain measurement data. The following interfaces are particularly suitable for coreIN sensors that also use measurement electronics from core sensing:

- coreVIEWER app for visualizing and recording data

- coreGATE gateway for 0…10V, USB, CANBUS, TCP/IP, MQTT

- coreCLOUD Dashboard for visualization in the cloud

- Documented API for BLE signals

Due to their position inside the component, coreIN sensors are generally well protected. Depending on the application, encapsulation can be used to achieve a high protection class for challenging environments.

coreIN sensors are ideal for obtaining measurement data from mechanically unchanged environments. However, the technology is also ideal for OEM products and series production.

Details coreIN Sensor

Induktive Energieversorgung

Über eine Spule, die um den Rotor gewickelt wird, wird über den Stator (Pickup) permanent Energie bereitgestellt.

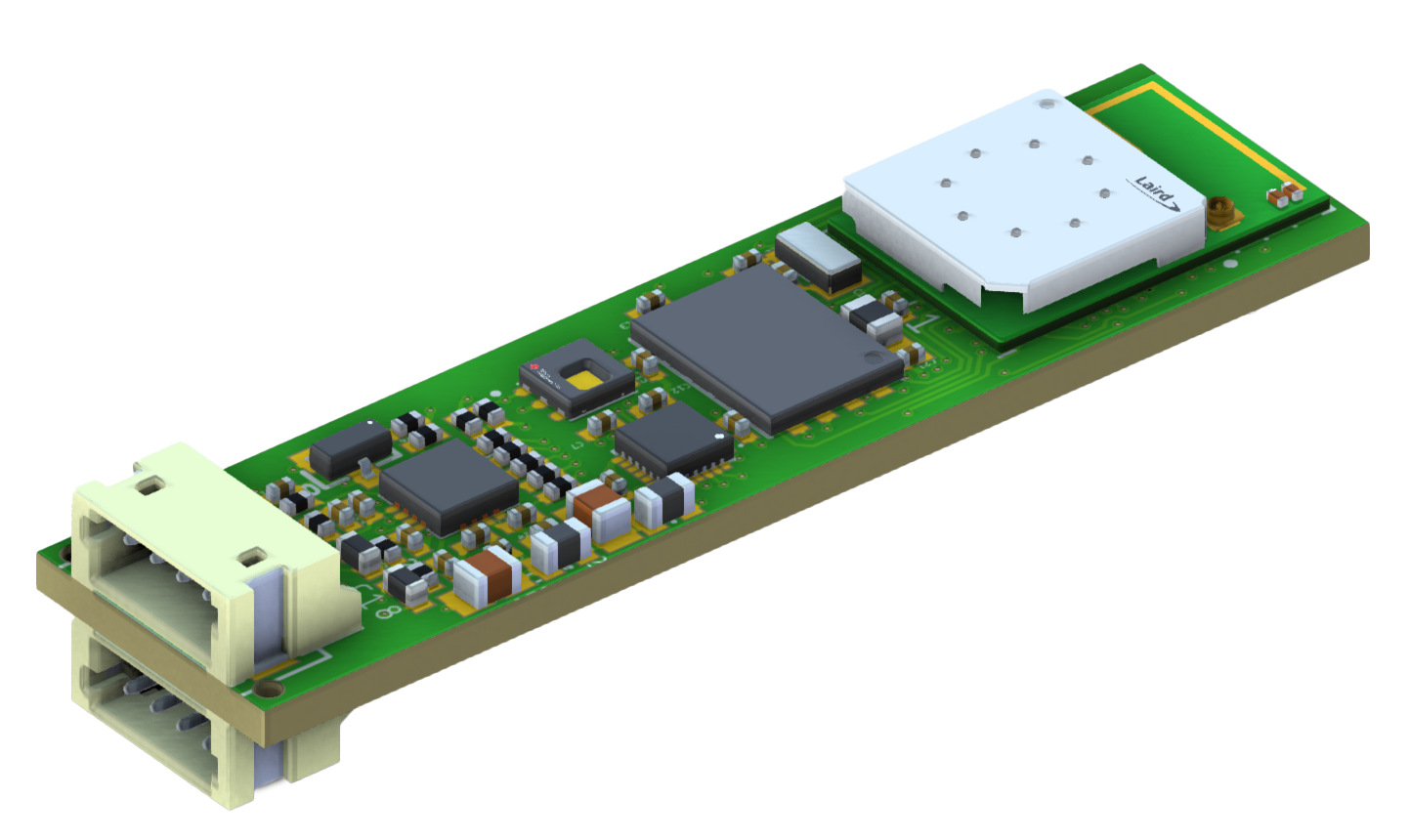

Messverstärker coreLIME

Größe 50x13mm

coreIN Sensorkörper

Größe 30 x 14...100mm

Li-Ion Akku oder Batterie

verschiedene Schnitstellen integriert oder aufbauend mit Kunststoff-Ring möglich (gilt ebenfalls für Antenne)

Gateway coreGATE

Vielfältige Standard-Schnittstellen, u.a. 0...10V, UARD, CANBUS, MQTT, TCPIP....

App coreVIEWER

Kostenfreie App zur Konfiguration, Live-Anzeige und Logging. Verfügbar für Android und IOS.

How to get your coreIN sensor

- Send us an email with the basic details of your planned sensor integration, and feel free to share any drawings, images, or CAD files with us.

- In an initial orientation meeting, a sensor specialist discusses the feasibility and desired configuration of the sensor, as well as any special features. The design also takes into account the expected resolution and quality of the sensor.

- We will prepare a quote for the sensor, whereby we can calculate using parts provided or have them manufactured by our partners. A typical delivery time for new coreIN sensors is 8 weeks after order placement.

- After delivery, a brief remote commissioning or training session is included in our offer. If desired, our data science specialists can assist with the evaluation and processing of the measurement data.

Get your customized integrated sensor

We look forward to hearing from you!