The simple way to measure torque

- No modifications to the drive train – ready for measurement immediately

- Wireless data transmission – flexible, mobile, secure

- Intuitive app operation – no special hardware required

- Suitable for development and series production—also for small series and individual items

- Measuring range 0.1 to 10 kNm – depending on shaft (expandable)

Advantages of torque drive shafts compared to conventional measuring adapters

| Integrated torque drive shaft | conventional torque sensor adapters |

|---|---|

| No mechanical changes to the drive train | Mechanically modified powertrain |

| Sensor and measurement electronics rotate with the shaft, plug and play | Stator and bearing block required, additional installation space |

| No wiring, integrated battery enables self-sufficient operation | Wiring and permanent power supply required |

| Configuration, data display, and logging via user-friendly app | Additional equipment and special expertise required |

| Additional measured variables: rotational speed, 3D acceleration | Usually only torque measurement |

| All existing protective housings and safety systems remain in place | Design changes, often critical to safety |

| Suitable for field tests, real-world operation, and series applications | Primarily suitable for laboratory use |

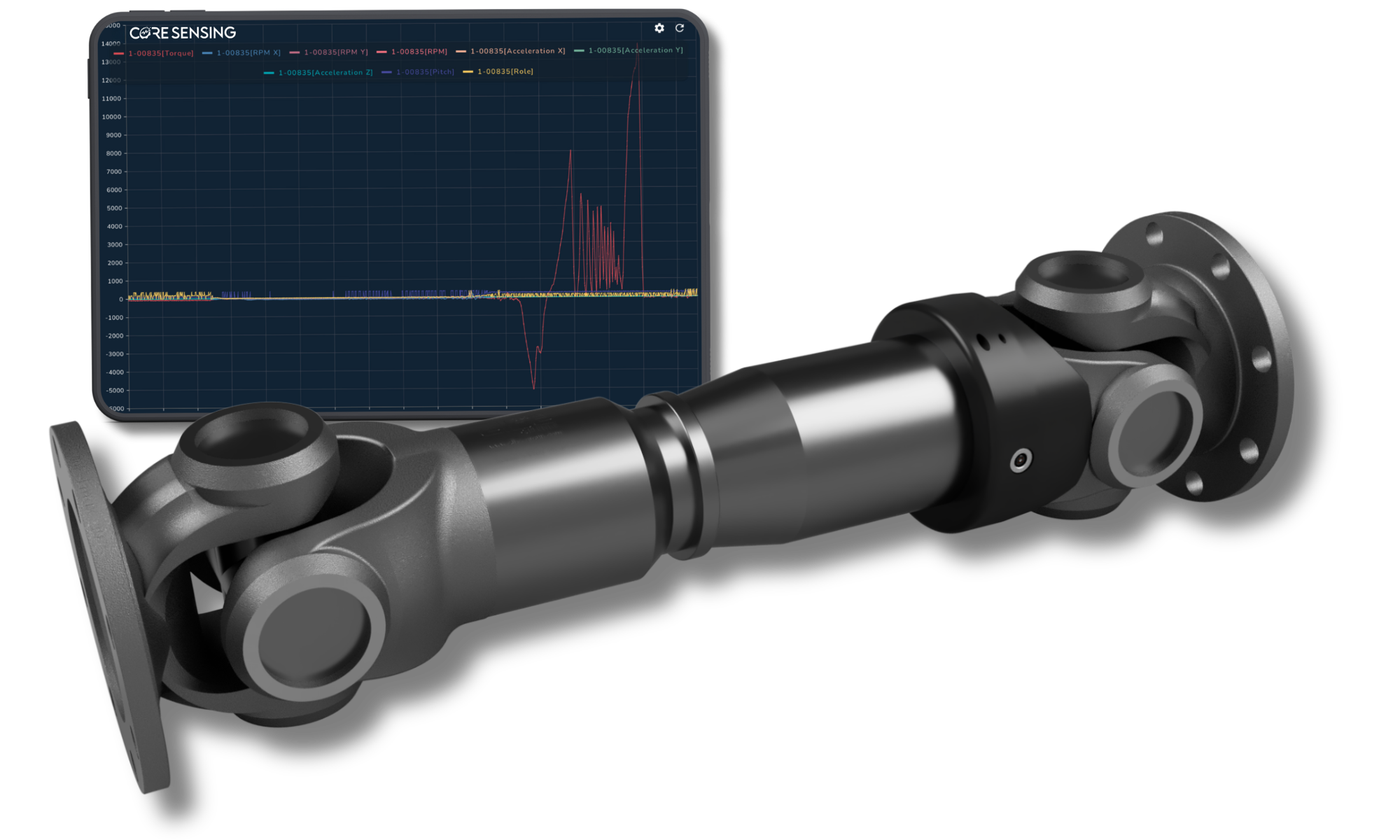

Industrial Cardan Shafts

For industry and vehicle manufacturing

Our preferred manufacturer for the integration of coreIN sensors in cardan, cross, and ball joint shafts is Elbe Group.

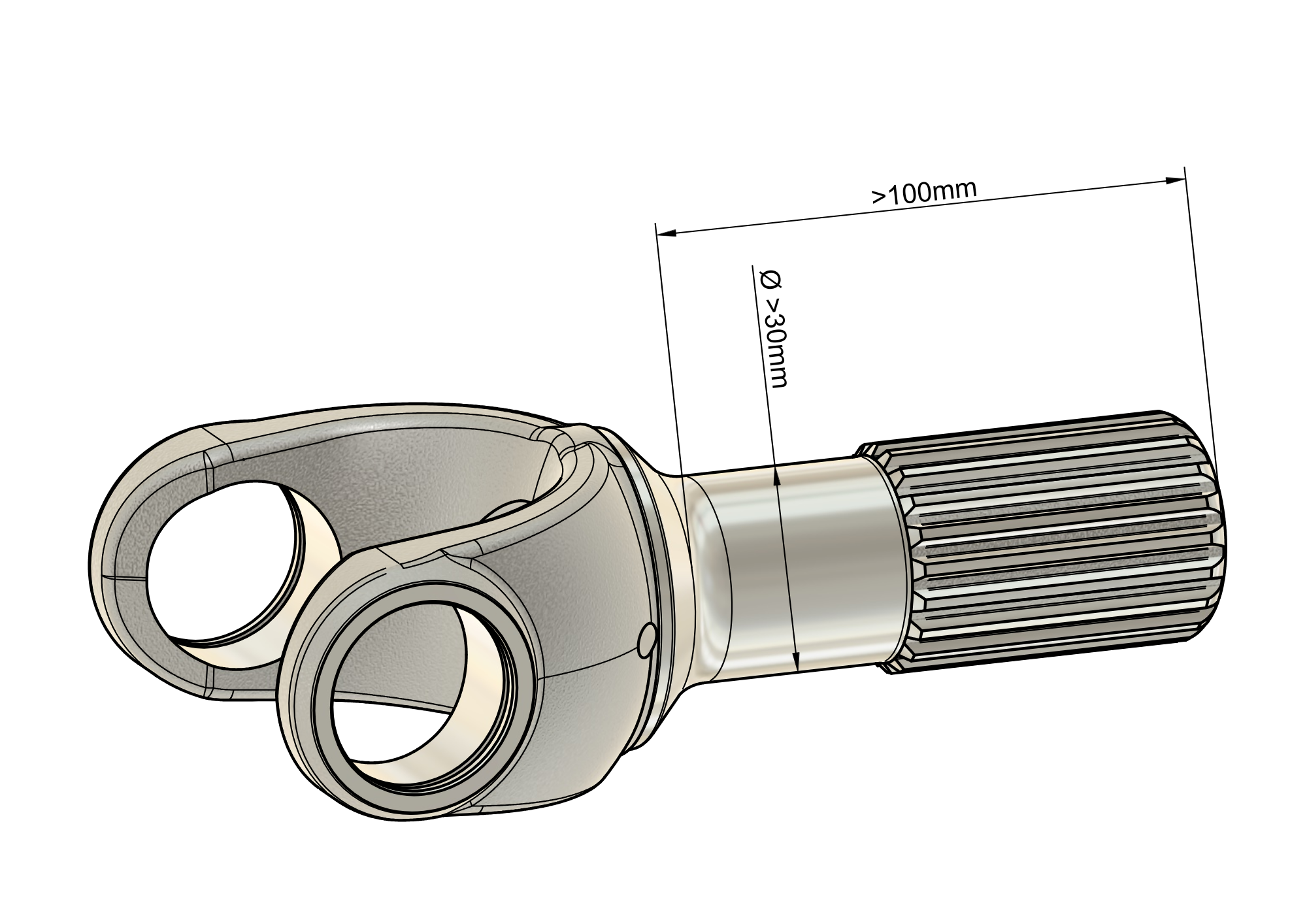

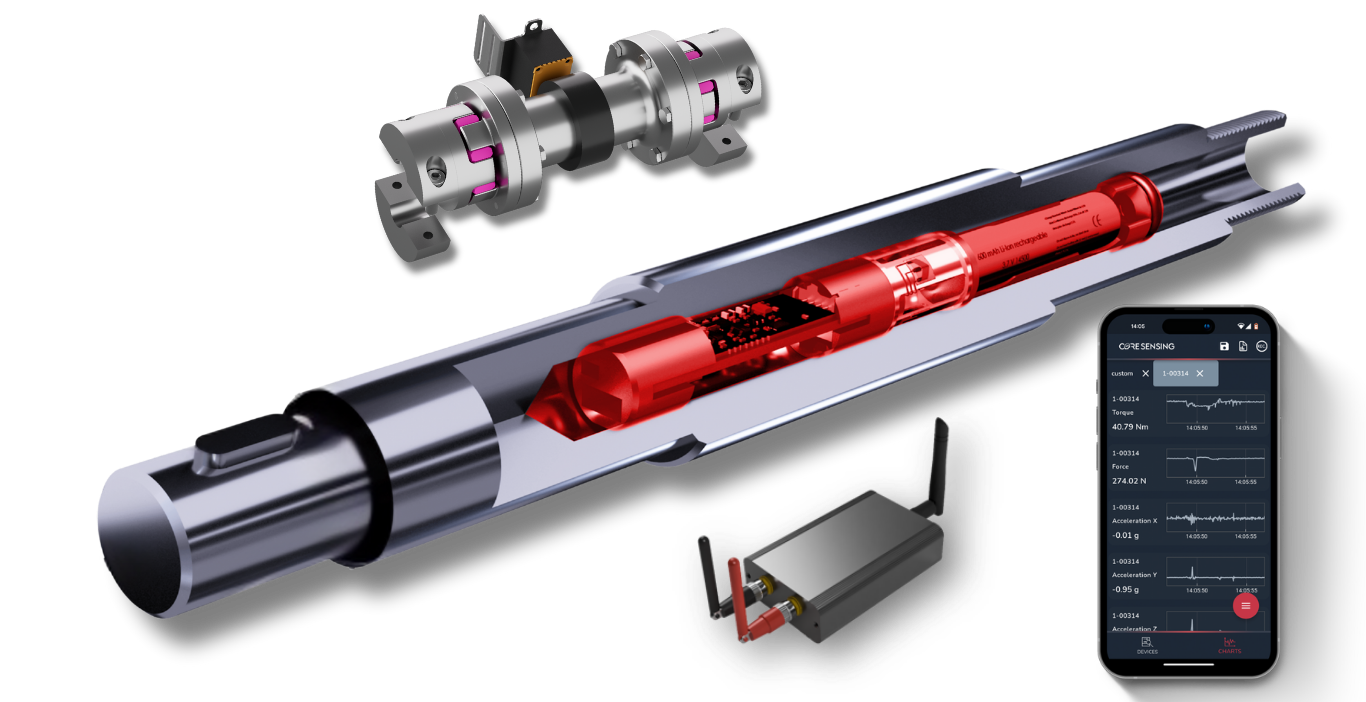

The sensor integration is achieved using a coreIN sensor, which is pressed into a precisely drilled hole in the profiled inner part of the length compensation device (sliding part). This creates a robust connection that enables accurate measurements without changing the design of the drive shaft.

The antenna and charging port are secured in place using a plastic ring in the fork area.

Power is supplied by an integrated, rechargeable Li-ion battery. Depending on the configuration, the battery capacity ranges from 2,800 to 5,200 mAh.

This enables a continuous operating time of 250 to 500 hours at a transmission rate of 1 signal per second. Depending on the application, this operating time can also be significantly extended. Please feel free to contact us for more information!

Depending on the application, a transmission frequency of up to 1,000 signals per second is possible. The setting can be easily adjusted as needed using the voreVIEWER app.

Depending on the installation situation, the radio range is up to 30 m. Gateways, external antennas, and repeaters also provide solutions for challenging environments.

- Visualization in the coreVIEWER app

- Logging to internal memory or mobile device

- PLC integration via coreGATE – e.g., 0-10V

- System integration via coreGATE – e.g., TCP/IP or MQTT

- Cloud dashboard via coreGATE – e.g., LTE or TCP/IP

- Research and development

- Condition monitoring

- Predictive Maintenance

- Safety Features

- End of Line Testing

PTO shafts

Für die Landwirtschaft

Our preferred PTO shafts for coreIN sensor integration are the series W2400 and W2500 from Walterscheid.

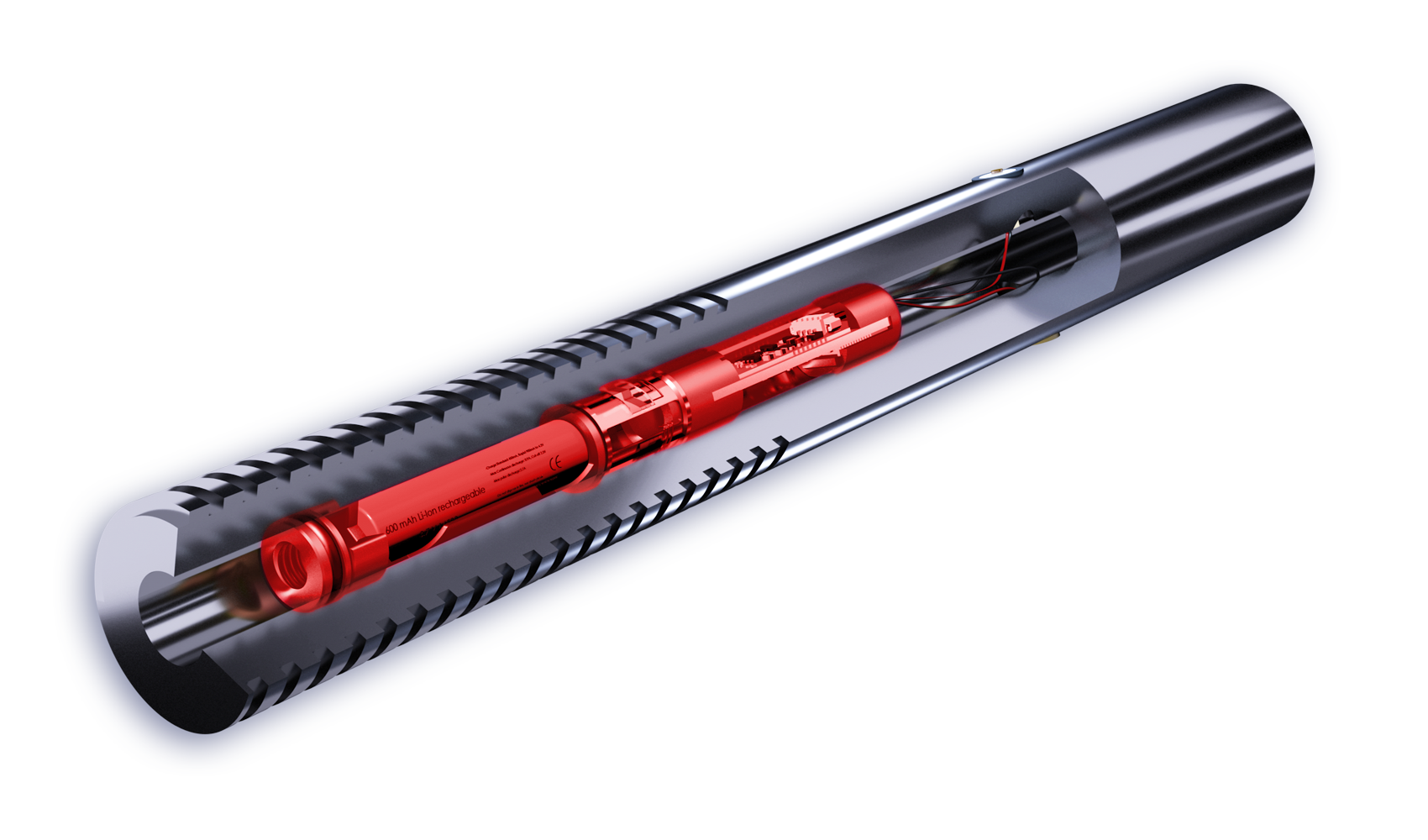

Sensor integration is achieved using a coreIN sensor, which is integrated into a S4 shaft This creates a robust connection that enables accurate measurements without changing the design of the drive shaft. This shaft can be shortened to any length before integration.

The antenna and charging connector are positioned at the front end of the shaft to prevent interference during operation.

Power is supplied by an integrated, rechargeable Li-ion battery. Depending on the configuration, the battery capacity ranges from 2,800 to 5,200 mAh.

This enables a continuous operating time of 250 to 500 hours at a transmission rate of 1 signal per second. Depending on the application, this operating time can also be significantly extended. Please feel free to contact us for more information!

Depending on the application, a transmission frequency of up to 1,000 signals per second is possible. The setting can be easily adjusted as needed using the voreVIEWER app.

Depending on the installation situation, the radio range is up to 30 m. Gateways, external antennas, and repeaters also provide solutions for challenging environments.

- Visualization in the coreVIEWER app

- Logging to internal memory or mobile device

- CAN bus integration via coreGATE CAN

- Cloud Dashboard via coreGATE LTE

- Research and development

- Field tests

- Test benches

Details coreIN Sensor

Induktive Energieversorgung

Über eine Spule, die um den Rotor gewickelt wird, wird über den Stator (Pickup) permanent Energie bereitgestellt.

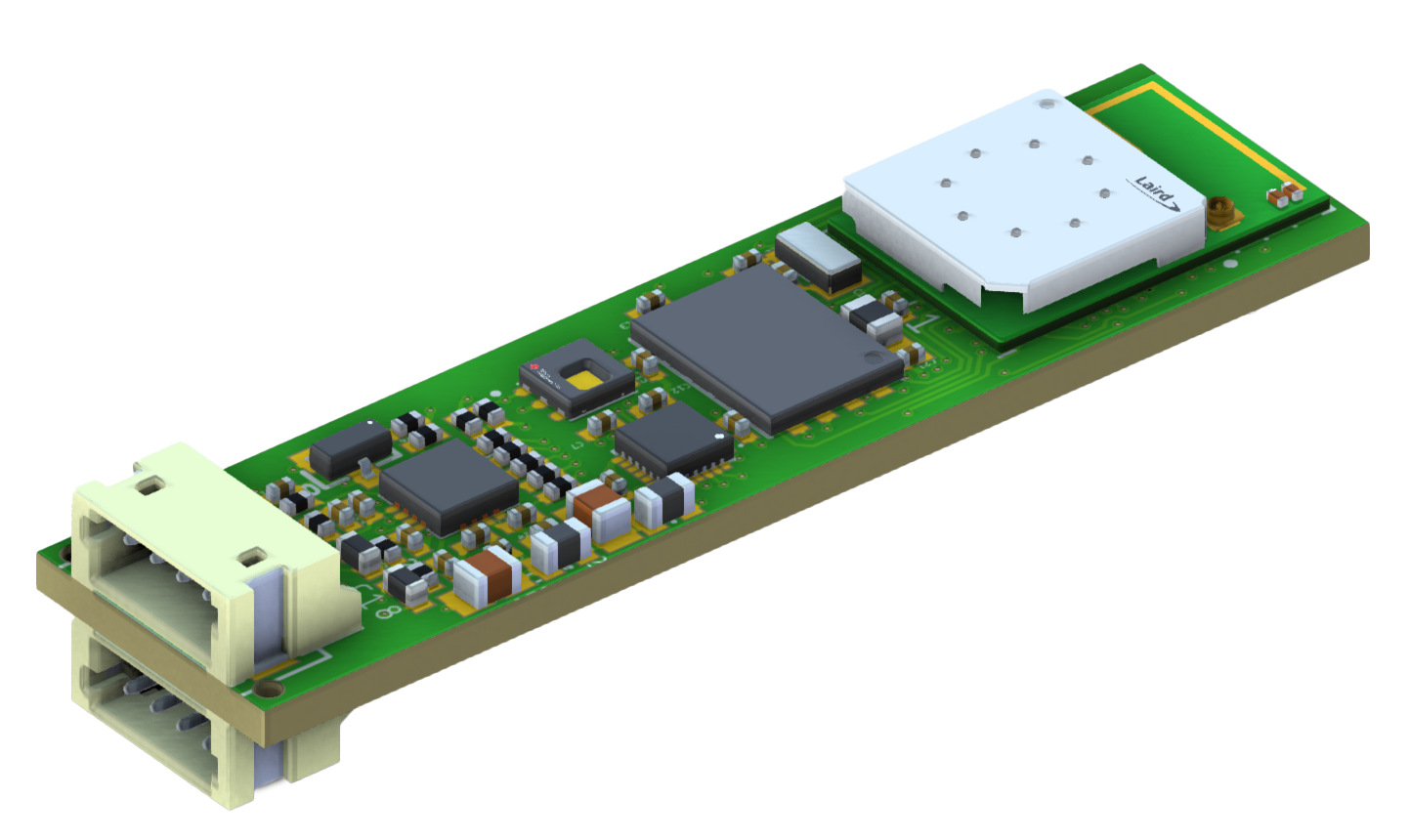

Messverstärker coreLIME

Größe 50x13mm

coreIN Sensorkörper

Größe 30 x 14...100mm

Li-Ion Akku oder Batterie

verschiedene Schnitstellen integriert oder aufbauend mit Kunststoff-Ring möglich (gilt ebenfalls für Antenne)

Gateway coreGATE

Vielfältige Standard-Schnittstellen, u.a. 0...10V, UARD, CANBUS, MQTT, TCPIP....

App coreVIEWER

Kostenfreie App zur Konfiguration, Live-Anzeige und Logging. Verfügbar für Android und IOS.

How to get your coreIN sensor

- Send us an email with the basic details of your planned sensor integration, and feel free to share any drawings, images, or CAD files with us.

- In an initial orientation meeting, a sensor specialist discusses the feasibility and desired configuration of the sensor, as well as any special features. The design also takes into account the expected resolution and quality of the sensor.

- We will prepare a quote for the sensor, whereby we can calculate using parts provided or have them manufactured by our partners. A typical delivery time for new coreIN sensors is 8 weeks after order placement.

- After delivery, a brief remote commissioning or training session is included in our offer. If desired, our data science specialists can assist with the evaluation and processing of the measurement data.

Get your customized integrated sensor

We look forward to hearing from you!