A leading company in the development and production of chemicals, in particular titanium dioxide pigments (TiO2) and performance additives, which are used in various industries such as cosmetics, pharmaceuticals, food, paints and coatings, is planning to use its additives in surface coatings to optimize the conductivity and performance of small ceramic components.

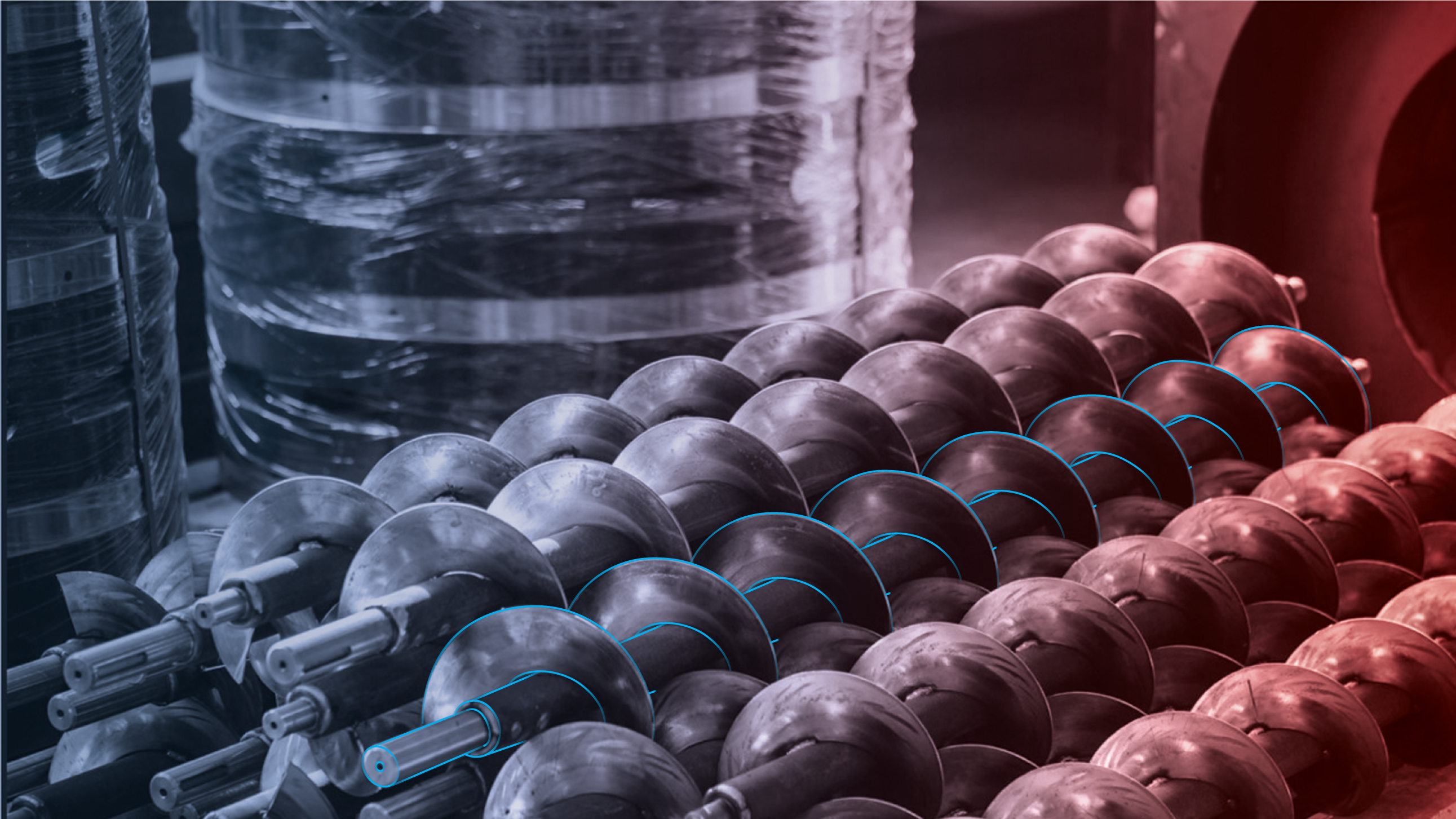

Avoiding failures in the material feed system - Efficient production thanks to smart sensors

Smooth operation of the leading chemical company's feeding systems is crucial in order to produce the additive that is optimally tailored to this application. In the past, however, there have been repeated problems that have led to unforeseen breakdowns of the 6-metre-long screw conveyor in the material feed area, resulting in downtime costs.

In order to prevent future failures of the material feeding system and minimize the associated costs, the company has opted for the individual integration of intelligent sensors from Core Sensing. These sensors enable the precise measurement of force, torque and temperature, which means that faults in the material feed system can now be detected intuitively. The expectation is that the company will be able to save a five-figure sum each year by avoiding downtime costs. This financial gain results from the increased efficiency of the material feeding systems, which is achieved by integrating the intelligent sensors from Core Sensing.

Preventive maintenance thanks to intelligent sensors: Monitoring of mechanical loads for optimum operating processes

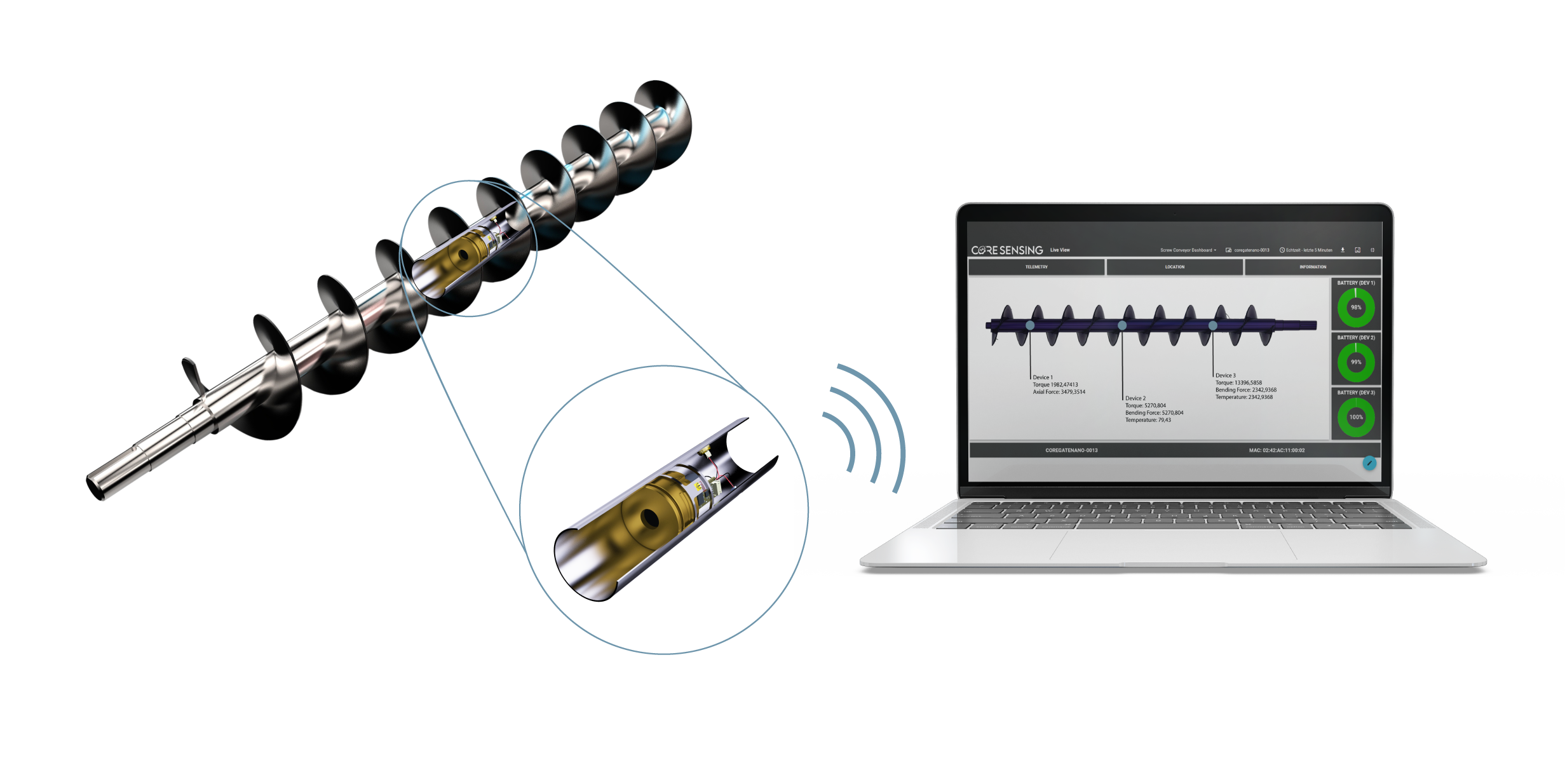

The smart technology records mechanical stresses or strains at the measuring point and forwards the relevant data directly. The modular system can use this data to predict impending failures.

In order to avoid future failures and also keep an eye on upstream and downstream processes, three coreIN-sensors inside the shaft. In combination with coreCLOUD these smart sensors enable remote monitoring of the voltages that occur. The machines now provide data that helps to operate the material feed systems optimally without the need for costly conversions.

Estimate remaining service life thanks to Predictive Maintenance Toolbox

Based on the load variables measured by coreIN inside the machine, the remaining service life of the drivetrain can be estimated in the context of Predictive Maintenance can be estimated. The coreANALYZE and corePREDICT tools from the core sensing toolbox are used for this purpose.

Both tools analyze the determined load spectra and present the results of the evaluation in a cloud dashboard specially developed for the company. Users can thus better understand the interactions within their feeding machines and are optimally equipped to deal with unforeseen malfunctions.

core sensing - your partner for predictive maintenance

Would you also like to keep your downtime costs as low as possible? Our sensor solutions can help you do this:

- Automated and scheduled execution of maintenance work

- Avoidance of unforeseen incidents

- Minimization of operational downtime costs

- Monitoring processes via remote access

- Generation of valuable data records for process optimization

- Monitoring the wear and tear and service life of your components

- Reduction of replacement processes by at least half.

Benefit from our sensor solutions and minimize your downtime costs. Through automated and scheduled maintenance work, we ensure the smooth operation of your systems and avoid unforeseen malfunctions that could cause costly downtime. Use remote monitoring to maintain an overview at all times and generate valuable data records for process optimization. With our expertise, you can keep an eye on the wear and tear and service life of your components and reduce replacement procedures by at least half, resulting in significant cost savings. Contact us now to find the right solution for your company together.