Intelligent sensors for commercial vehicles - ideal for predictive maintenance

The range of modern off-highway and commercial vehicles on the world market is enormous, and even the possible drive types are more diverse than ever before with gasoline, diesel, gas, electric and hydrogen. But as much as the vehicles differ in their application and function, they all have one thing in common: efficiency, economy, reliability and sustainability are the overriding challenges in product development.

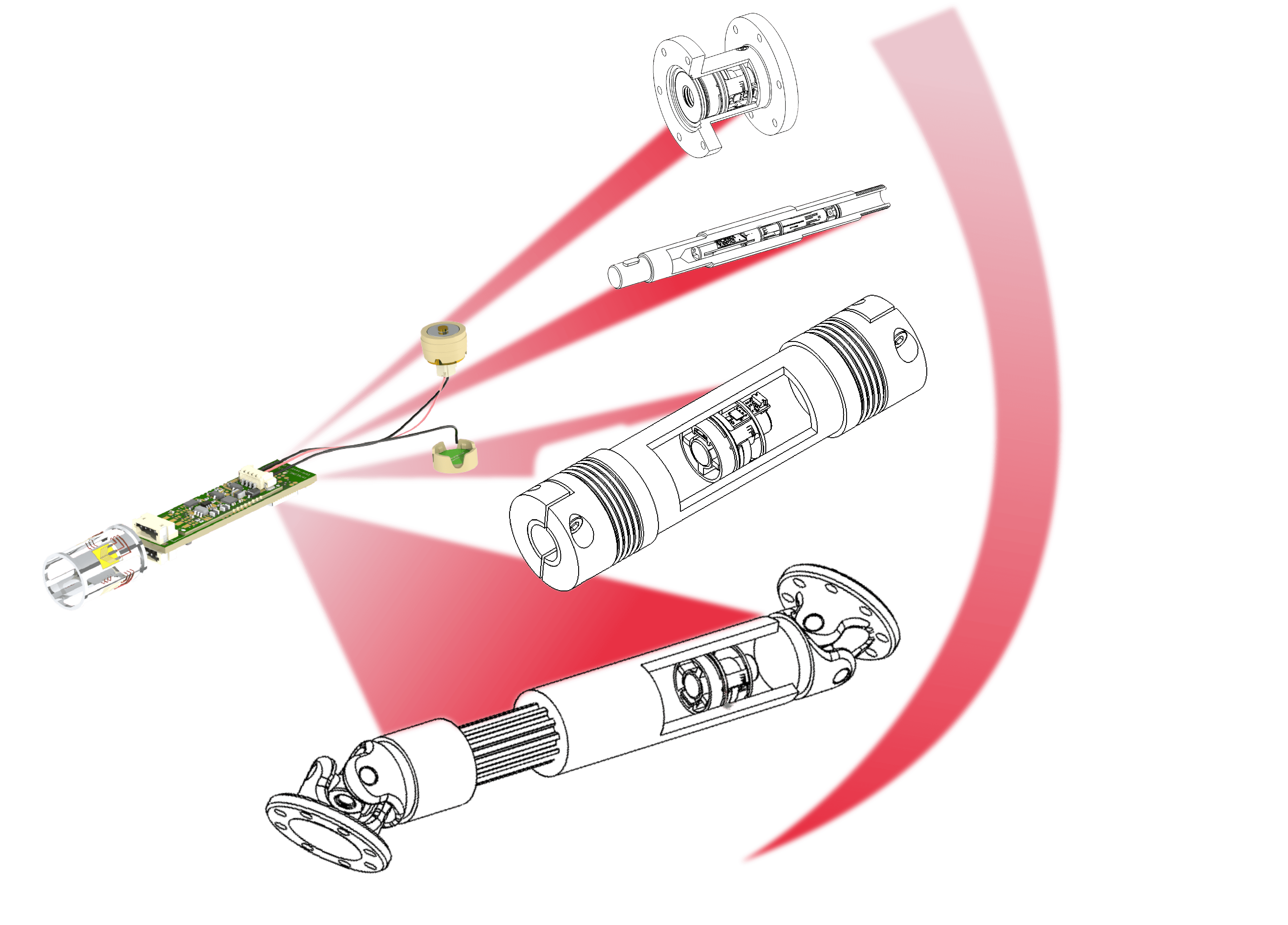

The integrated sensors from core sensing record stresses robustly and at meaningful points. Whether torque measurement in shafts of the main or auxiliary drive trains or tensile force detection in force measuring bolts. Our wireless sensor solutions work efficiently even under difficult conditions and are therefore particularly beneficial for your commercial vehicles, making them predestined for use in harsh environments.

Possible fields of application

- Agricultural technology

- Construction machinery

- Special commercial vehicles

- Motorsport

- Marine

- Railroad

You would like to learn more about our sensor technology and the application possibilities in harsh environments? Simply request further information.

Sensor technology for commercial vehicles - application examples

Drive train monitoring

Monitoring with torque sensors and simultaneous engine control can prevent high loads in extreme driving situations, so that general engine throttling or a heavily oversized powertrain can be dispensed with. In test operation or on the race track, an integrated torque sensor provides relevant insights into the stresses acting during a real drive. By simply replacing a component such as a clutch, cardan shaft or drive shaft with a sensor component from core sensing or its partners, sensor data can be acquired without any design changes.

Monitoring and control of power take-offs

The power take-off shafts of agricultural and construction machinery are used to drive machines such as harvesters, balers, seeders, log splitters, choppers, cutter bars, etc., which are connected by means of universal joint shafts. In many of these applications, the detection of the acting torques is essential to control the attachments, to indirectly gain information about crop, soil condition or equipment condition. The robust sensor solutions from core sensing are ideal for users and companies that want to learn more about the downstream processes at the power take-off.

Predictive maintenance

Finding the optimal time for maintenance and servicing is still a major challenge today. With the help of an integrated torque transducer from core sensing in the drive and auxiliary drive train, clear statements can be made about running times, load spectra and overloads. This means that maintenance intervals and the remaining service life of individual components and parts (e.g. mower blades, drills, cardan shafts) can be determined much more precisely than was previously possible.

Advantages of the IoT sensors from core sensing

Our sensors not only measure forces and torques, but also record a variety of other measured variables, such as speed, accelerations and temperature. Not only that: the robust, wireless sensors are protected inside the components and thus provide safe, reliable sensor values. Simply benefit from the following advantages:

Optimized for rotating and moving parts

Our performance begins where conventional manufacturers and transducers reach their limits. Our sensors can be integrated very easily into existing designs - whether as standard components or individual parts.

Optimized for harsh and demanding environment

Due to the sensor integration inside the component, our sensors are excellently protected against external influences.

Optimized for wireless use

Our sensors not only measure forces and torques, but also record a variety of other measured variables, such as speed, accelerations and temperature.

Sensor technology for commercial vehicles in practice

Determine power and torque through smart PTO

In agricultural vehicles, smart PTOs record torque and power between tractor and implement.

Learn more about our smart sensor technology for commercial vehicles. Arrange your non-binding appointment directly.