Smart sensor technology from HKS enables more efficient use of excavators

HKS Dreh-Antriebe GmbH has been developing, designing, producing and selling hydraulic and pneumatic compact drives for rotating and slewing masses for 50 years. The company is present in over 20 countries and is one of the leading international suppliers in its sector.

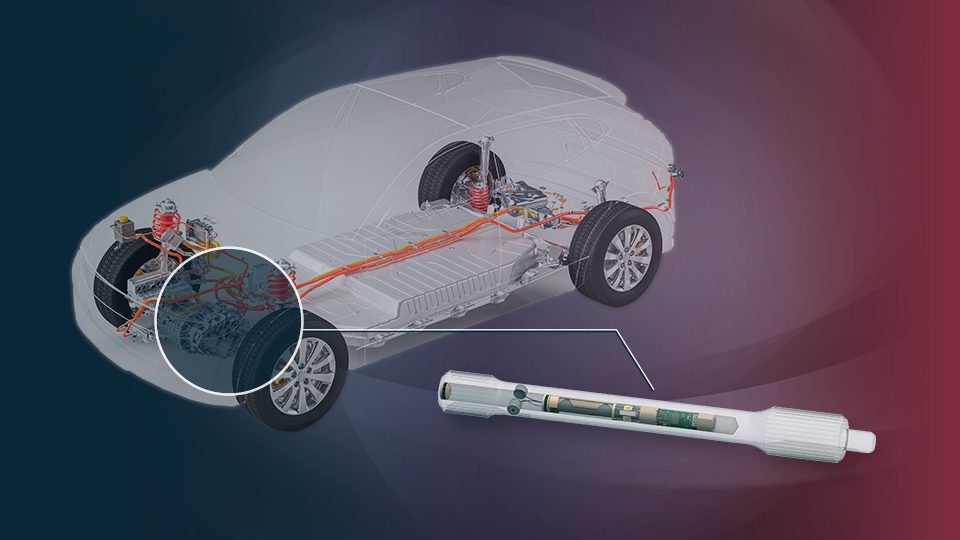

The rotary actuators of the XtraTilt series from HKS are in particularly high demand among well-known manufacturers of construction machinery and excavators - especially when the highest possible performance and variable application options coupled with reliability and low maintenance costs are required.

Avoidable failures due to incorrect use

Hydraulic rotary actuators for the construction equipment industry are designed for positioning and holding attachments. However, it is quite possible for machine operators to overload the actuator in an intended or unintended manner. For example, very high forces can occur when levering out stones or roots from the side, which can damage the drive. Collisions can also occur if the bucket is swiveled against an obstacle.

Assistance system for more optimal use

In order to guarantee maximum operational readiness of the part-turn actuators for all users in the future, HKS was looking for a solution to implement an intelligent assistance system. This was to provide reliable real-time feedback on the current load level of the slewing drive during operation of a construction machine. Machine operators thus get a better feel for these loads and can better assess whether the drive is suitable for a given task. In addition, real-time feedback allows the mode of operation to be adjusted according to the load level, enabling non-critical continued operation.

More availability with smart sensor technology

An essential prerequisite for the realization of an assistance system is precise measurement data from inside the component to be monitored. Powerful sensors are needed to record this data. In the case of HKS, these sensors must be able to be integrated into a compact hydraulic component with little effort, without negatively affecting its rigidity and strength.

The developers at HKS Dreh-Antriebe GmbH found what they were looking for at core sensing. With coreIN Darmstadt-based HKS supplies a smart torque sensor with minimal space requirements that can be easily integrated into the compact XtraTilt drives. Once integrated, the sensor determines the loads (torques) occurring in the component in both directions and sends them to a display in the excavator. Here, the loads are displayed in graphical form. The excavator operator recognizes the loads and can control them better. Overloading or component damage is thus avoided while at the same time ensuring optimum use within the excavator's design range. With the powerful IIoT gateway coreGATE core sensing HKS also supplies the solution for integrating the coreIN torque sensor into the existing data acquisition system.